Grinding

Home / Grinding / Cutting Tools Regrinding > Cutting Tools Regrinding Services

Resharpen Tools materials:PCD,PCBN,MCD,CVD,Carbide ,ceramic and Cermet.

Types of Regrinding cutting tools:Drills,Reamsers,End mills,Complex Forming Tools,MCD inserts,turning tools,PCD Rotary Tools.

Moresuperhard advantages:Get professional product application support throughout the tool life Professional grinding standard process Stable product quality high quality coating Short lead time

Moresuperhard provide professional regrinding services for various precise cutting tools.Moresuperhard has perfect grinding hardware, CNC tools grinder, manual tool grinder, coating equipment, complete regrinding hardware equipment.

Carbide Tools Regrinding

Carbide reamsers resharpening

The reamer is an alloy tool that is often repaired, and its regrinding is relatively simple. Due to the high precision, it can generally be repaired 2-5 times. Before regrinding, check whether the diameter is still within the required range. Reamers are generally not coated after grinding.

Regrinding specification: D3-D32, flute length≤300;

Regrinding Contents: cutting cone, excircle, edgeprocessing, groove polishing, coating, etc, or restructuring according to customers'requirements

Customer Notice: minimum length, minimum effective diameter, processed materials, life and other equirements must be explicitly told. Cylindrical regrinding keeps the original top.

Carbide end mills regrinding

The regrinding of the ball end milling cutter does not change the diameter, while the regrinding of the side edge of the flat end milling cutter will reduce the diameter, depending on the specific processing conditions of the user.

Regrinding Types: various steels and carbid materials, standard and non-standard mills of straight and tapered shanks, covering flat-head mills, ball-nosed mills, R-nosed mills, tapered mills, roughing mills, T-slot mills and molding contour mills;

Regrinding specification: D3-D50. flute length≤300;

Regrinding Contents: end edge, cutting edge, cutting edge, rake face or overall

Regrinding, edge processing, coating, etc, or restructuring according to customers' requirements;

Customer Notice: minimum length, minimum effective diameter, processed materials,life, restructuring and other requirements must be explicitly told.

carbide end mills before grinding carbide end mills after regrinding

Carbide drills Regrinding

Grinding type: standard drills, step drills and non-standard drills with various groove types and drill points;

Grinding specification range: D3-D32, groove length ≤ 300;

Grinding content: drill point, outer circle, step, edge passivation treatment, groove polishing, coating, etc., or customized according to customer requirements;

Notes for customers: requirements such as the shortest length, minimum effective diameter, processed material, service life, restructuring, etc. must be clearly informed.

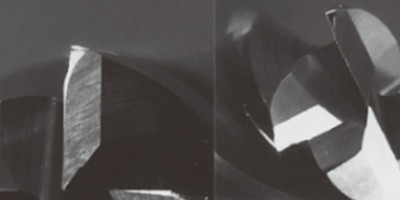

Comparison chart before and after grinding

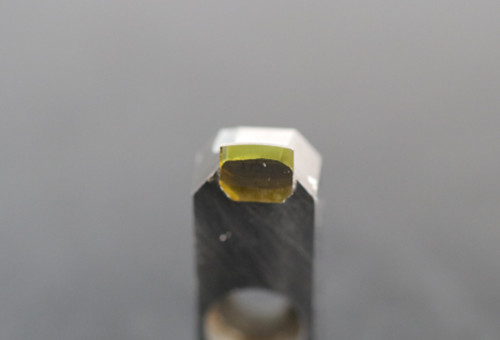

PCD (polycrystalline diamond )cutting tools Regrinding including PCD reamers,PCD drills,PCD end mills

The wear of PCD tools generally has the following situations: Mechanical wear, adhesive wear, reverse transformation (phase change) wear, chemical wear, diffusion wear, bonded wear, micro-fracture wear, abnormal wear.

PCD Cutting Tools Wear Form: Rake wear, flank wear.

Blunt standard: The average flank wear width VB=0.3mm.

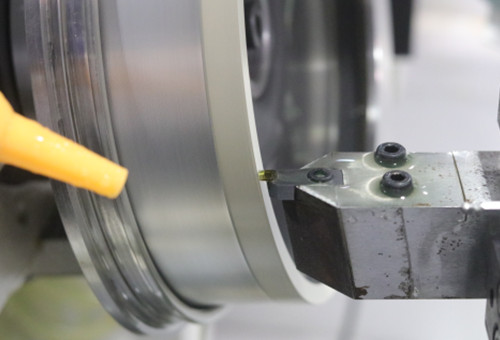

PCD Cutting Tools Regrinding plan

1. Determine the regrinding limit and scrapping standard according to customer requirements;

2. Check whether the blade has a large chipping or a large amount of wear;

3. Formulate grinding drawings and grinding processes according to the grinding limit and grinding requirements provided by customers;

4. According to the requirements of the drawing, group the blades according to the size and perform batch grinding;

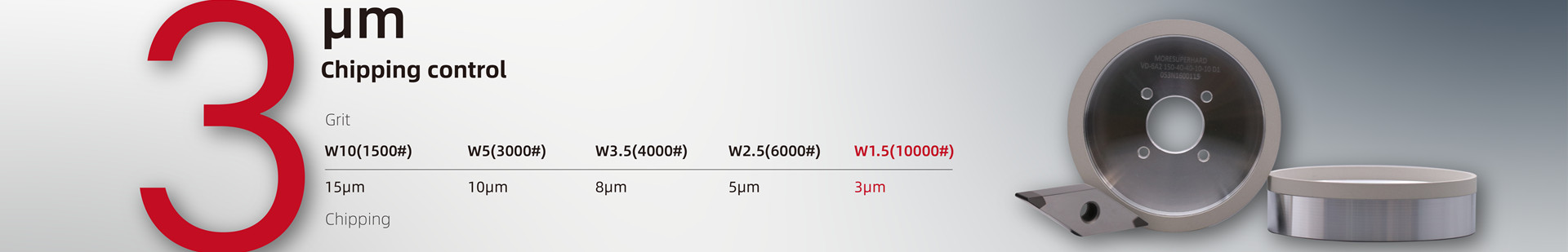

PCD Tools Regrinding Standards

1. The head of the tools body on the blade is clean and tidy, free of foreign matter, no cracks or rust on the surface, and no chipping of the blade;

2. The rake angle and rear angle remain unchanged after grinding;

3. The thickness of each blade is the same;

4. Radial runout tolerance of cutting edge is 0-0.05mm;

5. The runout tolerance of the end face of the blade is 0-0.03mm; 6. Grinding feed: generally 0.002~0.01mm each time.

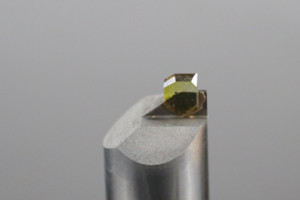

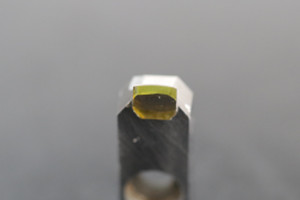

MCD /CVD tools regrinding including Single crystal diamond engraving tools,3C industry diamond tools and optical diamond tools

Tool types that can be resharpened:Single crystal diamond engraving tools,3C industry diamond tools and optical diamond tools

MCD diamond engraving tools used in jewelry

MCD Highligh Tools on 3C industry

CVD diamond tools

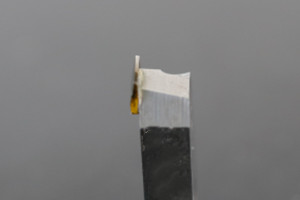

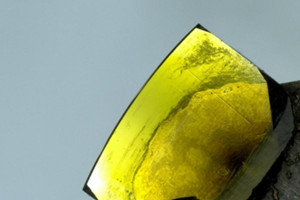

Effect comparison before and after regrinding

before regrinding (chipping:41μm) after rough regrinding (chipping:5μm-7μm)

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088