Grinding

Home / Grinding / Cermet Tools Grinding > Regrinding of Cermet Cutting Tools

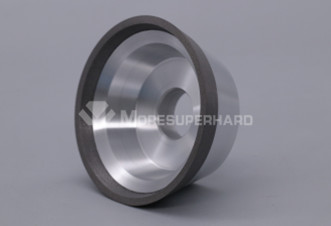

Available mold: 1A1,1V1,3V1,11V9,14A1,4B1,1E1 etc,.

abrasives:diamond

Bond:resin ,metal ,ceramic and hybrid bond.

Regrinding cermet tool types :ceremt end mills ,cermet resmers,cermet drills,cermet full form tools

Why cutting tools need to be reground?

Cutting tools reconditioning make cutting tool perform to its best performance time after time. Compared with purchasing new cutting tool products, metal grinding service can help customers reduce the cost of cutting tools by 50%. Take full advantage of the innovative technological advantages of cermet cutting tools , and at the same time, through the tool regrinding , the cutting tools can be restored to almost the same performance as when they were purchased.

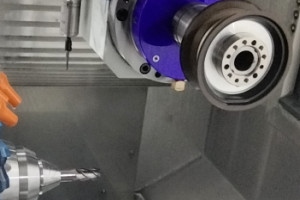

Case of regrinding Cermet end mills

Condition of the cermet tool being ground:Severe wear and tear, some end edges are chippedSevere wear and tear, some end edges are chipped

Regrinding steps:First, use 120# grinding wheel on the tool grinder to repair the original end edge, and then re-make the end edge and chip pocket

The processing parameters are as follows:

Grinder: Tuowa TW518

Grinding wheel:

3V1 100X31.75X10X4X45° D64-K5 for grinding chip pocket

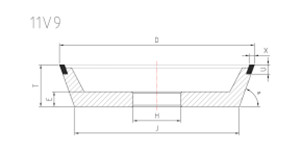

11V9 100X31.75X4X10X35T D64-S Grinding the first relief angle and the second relief angle;

Cooling: oil cooling;

Workpiece: 10mm four-blade cermet milling cutter;

Grinding parameters: chip flute: 3V1 grinding wheel, line speed: 18m/s; Feed: 10mm/min, horizontal pull: 8mm/min;

End blade relief angle: 11V9 grinding wheel, line speed: 21m/s; Feed: 1st relief angle feed and 2nd relief angle feed: 11mm/min

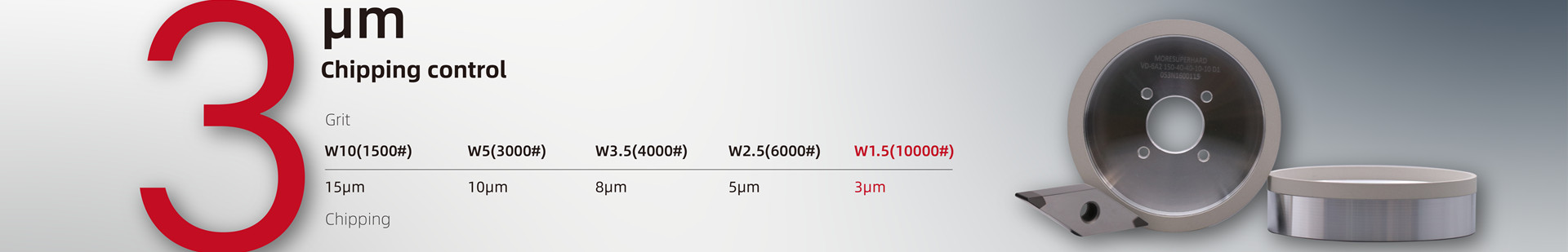

Grinding law of cermet materials:

1. After grinding all the deep cutting tools, the cutting speed is determined according to the power of the equipment and the characteristics of the material. Generally, it is one-half of the cutting speed of grinding carbide milling cutters of the same specification;

2. The chipping is related to the material properties of the bar, which can be solved by choosing different particle sizes;

3. Increase the pressure of the cooling oil in the grinding process to improve the cooling effect;

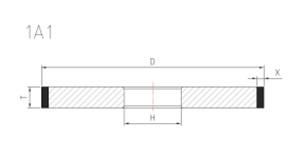

Commonly used grinding wheel specification drawings

| Mold | Drawing | Specification | |

| 1A1 |

|

1A1 D*T*H*X | |

| D | 100-400 | ||

| X | 3-25 | ||

| T | 3-50 | ||

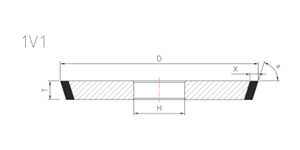

| 1V1 |

|

1V1 D*T*H*X | |

| D | 100-400 | ||

| X | 3-8 | ||

| T | 3-35 | ||

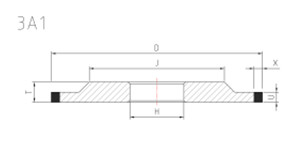

| 3A1 |

|

3A1 D*T*H*X | |

| D | 100-400 | ||

| X | 3-10 | ||

| T | 5-50 | ||

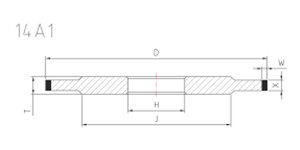

| 14A1 |

|

14A1 D*T*H*X | |

| D | 100-400 | ||

| X | 3-10 | ||

| T | 5-50 | ||

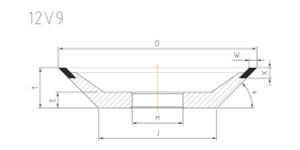

| 11V9 |

|

11V9 D*T*H*X | |

| D | 100-150 | ||

| X | 3-10 | ||

| T | 35-50 | ||

| 12V9 |

|

12V9 D*T*H*X | |

| D | 100-150 | ||

| X | 1.5-3 | ||

| T | 20-25 | ||

Why choose Moresuperhard diamond grinding wheel for regrinding cermet cutting tools

1.With a high holding force, the metal matrix and the diamond particles can form an effective chemical-metallurgical bond.

2.The abrasive exposure rate is high, which can reach 70%-80%. Good machining accuracy.

3.Suitable for ultra-precision grinding operations with good accuracy and surface finish.

4.Service life increased by 2.5 times and MRR increased by 30%. Lower cutting specific energy and better heat dissipation are beneficial to reduce power loss and avoid burning workpieces.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088