As key equipment in modern energy conversion and power systems, turbines require extremely high precision and quality in their manufacturing and maintenance processes. The grinding of turbine rotor grooves is one of the important processes, which directly affects the performance and life of the turbine. In recent years, ceramic CBN (cubic boron nitride) grinding wheels have gradually become an ideal choice for grinding turbine rotor grooves due to their excellent hardness, wear resistance and thermal stability. This article will explore the application and advantages of ceramic CBN grinding wheels in turbine rotor groove grinding.

Ceramic CBN grinding wheels are made of cubic boron nitride crystals and ceramic bond. Cubic boron nitride is a superhard material whose hardness is second only to diamond, but has better thermal stability and chemical inertness. Ceramic bond provides good strength and heat resistance, allowing the grinding wheel to maintain stable grinding performance under high temperature and high pressure conditions.

High hardness and wear resistance: It can maintain sharpness for a long time, reduce grinding wheel wear during grinding, and extend service life.

Good thermal stability: not easy to deform or fail under high temperature conditions, suitable for grinding difficult-to-machine materials such as high-temperature alloys and quenched steel.

Chemical inertness: It is difficult to react chemically with the materials being processed, maintaining the purity and precision of the processed surface.

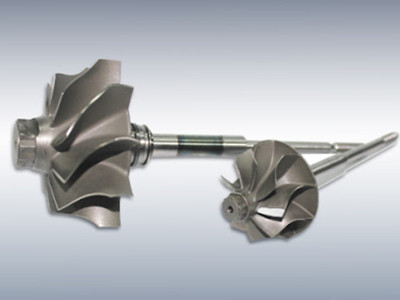

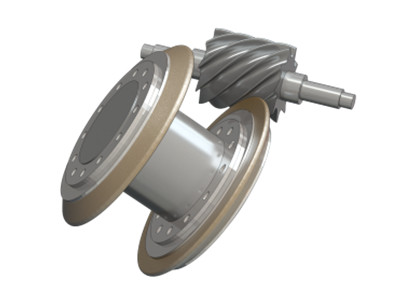

High precision requirements: The geometry and dimensions of the rotor slots need to be highly precise to ensure balance and efficiency of the turbine when rotating at high speeds.

Material properties: Turbine rotors are usually made of high-strength, high-hardness alloy materials. These materials are difficult to machine and place high demands on grinding tools.

Thermal effect control: The high temperature generated during the grinding process may cause thermal damage or deformation of the rotor material, so effective cooling measures are required.

Improve processing efficiency: The high hardness and wear resistance of ceramic CBN grinding wheels enable them to maintain efficient cutting capabilities during the grinding process, reduce the frequency of shutdowns and wheel changes, and improve overall processing efficiency.

Ensure machining accuracy: Because the ceramic CBN grinding wheel has good dimensional stability and wear resistance, it can maintain precise geometry during long-term grinding processes, ensuring the machining accuracy of the rotor grooves.

Reduce thermal damage: The good thermal stability and thermal conductivity of ceramic CBN grinding wheels help to quickly dissipate heat, reduce the temperature of the grinding zone, and reduce the risk of thermal damage and deformation of the workpiece.

Extended tool life: Compared with traditional grinding tools, ceramic CBN grinding wheels have a longer service life, reducing the cost and time of frequent tool replacement and improving the economic benefits of the production line.

Ceramic CBN grinding wheels have been widely used for grinding various types of turbine rotor grooves. The following is a customer case:

Moresuperhard 's Southeast Asian customers use Moresuperhard's ceramic CBN grinding wheels to grind turbine rotor grooves made of cobalt-nickel-iron alloy. In preliminary experiments, significant results were achieved by optimizing grinding parameters such as rotational speed, feed rate and coolant flow. Compared with traditional grinding wheels, the processing efficiency of ceramic CBN grinding wheels is increased by 30%, the surface roughness of the rotor groove is reduced by 20%, and the service life of the grinding wheel is doubled. Customers mainly use ceramic CBN cylindrical grinding wheels and ceramic CBN form grinding wheels to grind turbine rotors and rotor grooves.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088