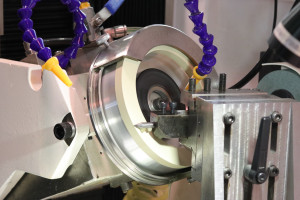

Grinding Site Conditions

A customer from South America has been purchasing 6A2 ceramic diamond grinding wheels from Moresuperhard company for grinding PCD cutting tools. Customers have always been satisfied with the grinding wheels provided by us, but when the order was placed on November 14, 2023, the blades jumped during use and the grinding wheels turned black. After the customer reported the problem, Moresuperhard quickly summoned experienced engineers to analyze the cause of the blackening of the grinding wheel during grinding.

Possible causes and solutions for grinding wheel blackening

The hardness of the grinding wheel is too high

A grinding wheel with too high hardness makes it difficult for the abrasive grains to fall off. You should choose a grinding wheel with moderate hardness to ensure that the abrasive grains can fall off quickly and keep the grinding wheel sharp.

Grinding wheel clogging

After grinding a large number of workpieces, the debris fails to fall off in time and adheres to the surface of the grinding wheel to form a blockage. The diamond grinding wheel needs to be polished regularly with a whetstone or dressing wheel to ensure that the surface of the grinding wheel is clean.

The temperature of the grinding wheel is too high

The heat continues to increase during the grinding process. It is necessary to increase the amount of coolant to reduce the temperature of the workpiece and the grinding wheel to ensure that the grinding wheel can work normally.

Excessive feed amount

The grinding wheel feed amount is large, resulting in an increase in cutting thickness and an increase in grinding temperature. The grinding wheel feed can be moderately reduced to reduce heat generation and prevent the grinding wheel from turning black.

Moresuperhard After-sales service

Our engineers have provided corresponding adjustment suggestions to customers and will continue to track customer feedback. We are responsible for every customer and every product, and are committed to providing customers with high-quality solutions.Through timely problem analysis and solution provision, we believe that customers will be able to perform grinding wheel grinding operations more smoothly in the future. Thanks to our customers for their feedback, we will continue to provide you with excellent products and services.

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088