Fields of application of CBN tools

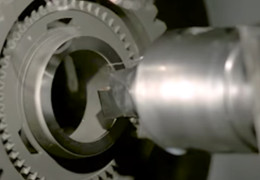

At present, CBN cutting tools are widely used at home and abroad, especially suitable for cutting difficult-to-machine materials industries, such as automobile manufacturing industry (engine, crankshaft, brake disc, brake drum, etc.), mining machinery industry (rolling mortar wall, slag Slurry pumps, etc.), bearing gear industry (hub bearings, slewing bearings, wind power bearings, gears, etc.), roll industry (cast iron rolls, high-speed steel rolls, etc.), etc.

The characteristics of CBN tool cutting

1. Suitable for processing high hardness materials

Since the hardness of the CBN tool itself is second only to diamond, it is collectively referred to as a superhard tool together with diamond PCD tools. CBN tools are mainly suitable for processing high-hardness ferrous materials, high-hardness wear-resistant cast iron and powder metallurgy materials. The hardness is generally above HRC45.

2.Turning with large allowance possible

Integral CBN cutters can achieve large margin rough machining, and the cutting depth can reach 8mm, which can fill the entire blade, and the production efficiency can be doubled.

3.High speed cutting

Due to its good performance, CBN cutting tools can fully realize high-speed cutting, and can be perfectly combined with CNC machine tools to efficiently cut workpieces and greatly improve production efficiency. The cutting speed of CBN tool finishing can reach up to 1500m/min without considering the rigidity and clamping method of the machine tool. Gray iron enables high speed cutting with good finish and dimensional accuracy.

4.Dry cutting

Due to the high thermal red hardness of CBN tools, if coolant is added, the blade is prone to breakage due to a sudden drop in temperature. Therefore, dry cutting is generally used when CBN tools process workpieces, especially in the case of intermittent cutting. Dry cutting not only Save a certain cost and be environmentally friendly.

Moresuperhard provide quality CBN/PCBN blanks and all set grinding solutions for CBN tools.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088