As the provider of driving energy, the automobile engine is known as the heart of the automobile. The processing quality of its parts determines whether the engine can output power economically and efficiently to drive the vehicle.

In the processing of automobile engine cylinder block and cylinder head parts, milling is very important. Mainly reflected in the following aspects:

1.Milling processing takes a long time and has a greater impact on the processing cycle of the entire production line

2.The consumption of milling blades accounts for a large proportion of the entire part processing cost

3.The milled surface will be used as the positioning datum between processes, which has a greater impact on the quality of the final product

4.The milled surface is still an assembly benchmark, and its surface quality directly affects the assembly accuracy and performance of the engine

More cutting tools has developed face milling cutter solutions for different workpiece materials based on the characteristics of engine parts.

Aluminum alloy material processing

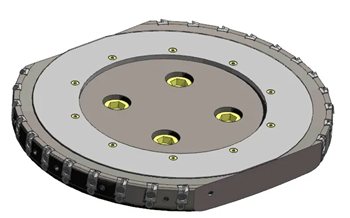

This tool directly welds the PCD blade to the tool holder, and the axial runout of each tool tip can be precisely adjusted through the adjustment mechanism on the tool holder. The tool holder is locked on the cutter head radially with screws, which occupies a small space, can achieve a dense tooth design, and improve processing efficiency. The blade installation groove is designed as a dovetail groove structure, the tool will not fly out even if the locking screw damages the blade during high-speed processing, ensuring the safety of personnel and equipment.

The cutter head is made of aviation aluminum alloy material, the weight of the cutter head is greatly reduced, and the stability during high-speed processing is improved. The surface of the cutter head has been anodized, and the wear resistance is significantly improved, which is beneficial to improve the service life of the cutter head. The cutter head is designed with an internal cooling structure to ensure a good cooling and chip removal effect.

Case:

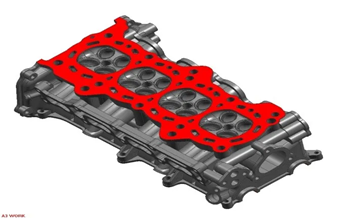

Finish milling of joint surface of aluminum alloy cylinder head

Cutter head: Φ220 mm (Z=22)

Blade: PCD blade

Processing parameters:

Vc= 2800 m/min;

N = 4050 rpm;

Fz= 0.08 mm/r;

F=7130 mm/min

Tool life: 12000-16000 pcs

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088