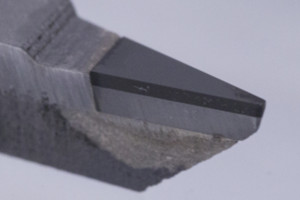

PCD or PCBN cutting tools have the highest qualityrequirements. Precise geometries and minimalchipping are the essential quality requirements.

6A2 vitrified diamond grinding wheel and peripheral diamond grinding wheel are commonly used for grinding PCD/PCBN cutting tools.The choice of grinding paraments is very crucial.

Recommand grinding paraments for grinding PCD tools and PCBN tools(grinding case)

6A2 vitrified diamond grinding wheel for grinding PCD cutting tools

| Diamond grinding wheel specifications | 6A2H 150*40*40 |

| workpiece | PCD mount plate |

| Grinding machine | Coborn R9 |

| Coolant | water |

| Stock | 0.3mm |

| Grinding Speed | 18m/s |

| Results | low wear chipping <10μm,10% less contace time |

Perpheral diamond grinding wheel for grinding PCD indexalbe inserts

| Diamond grinding wheel specifications | 12A2T 400*28*340 |

| workpiece | PCD -mounted plate |

| Grinding machine | Agathon 400 PENTA |

| Coolant | Blaser Grindlyte |

| Dressing interval | 6per cutting tools |

| Stock | 0.12mm |

| Grinding Speed | 25m/s |

| Results | 10% less wear Minimal chipping |

Moresuperhard manufactures a full line of insert grinding wheels for carbide, ceraric, cermet and PCD/PCBN materials.Diamond grinding wheels are designed with the optimal specifications considering the cycle time and dressing intervals for optimum praductivity. Moresuperhard diamond grinding wheel perforance is excellent, therefore, grinding inserts with a superior fnish and chip-free edge.

<< :Different Applications of CVD diamond plate

<< :what type of grinding wheels are used to grind pcd inserts?

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088