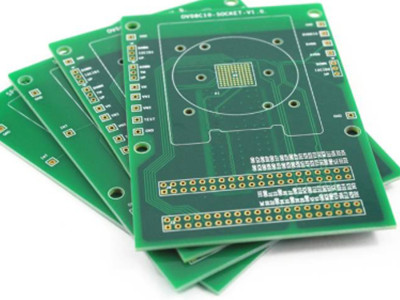

What is PCB board?

PCB, also known as printed circuit board, is one of the basic components of the electronics industry. Almost all electronic equipment, ranging from electronic watches and calculators to computers, communication electronic equipment, and military weapon systems, all use PCBs. As long as there are electronic components such as integrated circuits, in order to make the electrical interconnection between the various components , you need to use PCB.

Components of PCB circuit board

PCB is composed of insulating base plate, connecting wires and pads for assembling and welding electronic components. It has the dual functions of conductive lines and insulating base plate.

Why do you need to cut PCB?

Evaluation of circuit board quality and process improvement requires slicing as a basis for objective inspection and judgment. Slice analysis using metallographic equipment is an important means to check the thickness of PCB/PCBA internal circuits, number of layers, through hole aperture size, through hole quality observation, PCB/PCBA solder joint cavity, interface bonding status, and wetting quality evaluation. Analyze the microscopic details of PCB slices through metallographic microscopes and scanning electron microscopes. Poor-quality slices can lead to serious misleading and misjudgment of failure analysis. As the most important analytical equipment, the metallographic microscope has a magnification range from 50 times to 1000 times, and the measurement accuracy deviation is less than 1 μm.

How to cutting PCB slicing?

General cutting method can be divided into vertical slices and horizontal slices.

1.The vertical slice is cut in the direction perpendicular to the plate surface to observe the profile condition, which is usually used to observe the quality of the hole after copper plating, the laminated structure and the condition of the internal bonding surface. Vertical slicing is the most commonly used method in slice analysis.

2. The horizontal section is ground down layer by layer along the superimposed direction of the board to observe the condition of each layer, which is usually used to assist the analysis and determination of quality anomalies in the vertical section, such as short or open anomalies.

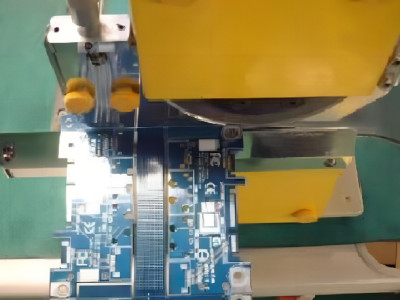

Metal diamond cutting wheel for PCB board

Metallographic cutting disc refers to the outer ring belt of the grinding wheel as the abrasive working layer, and the center is made of high-strength and high-rigidity metal material. It is also called the outer ring-type cutting wheel. Metallographic cutting discs have small slits, smooth cutting surfaces, and good rigidity. They are mostly used for cutting in metallographic laboratories.

High hardness: Metallographic cutting blades are usually made of diamond particles or other hard materials. They have high hardness and can effectively cut various PCB materials.

Strong wear resistance: The cutting edge of the metallographic cutting disc has been specially treated to have good wear resistance and can maintain a long service life.

High cutting accuracy: The metallographic cutting disc has good stability during cutting, precise cutting lines, and can obtain high-precision sample shape and size.

Good surface quality: The surface roughness produced during the cutting process of metallographic cutting discs is low, and the sample surface is highly flat, which is beneficial to subsequent sample preparation and microscopic observation. Wide applicability: Metallographic cutting blades are suitable for cutting various metal materials, including steel, copper, aluminum, nickel alloys, etc., and can meet the sample preparation needs of different materials.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088