We can supply single crystal diamond stone for diamond side milling tools,the holder is tungsten steel that not easy to heat and reduce the number of tools changes.The cutting edge is observed under the microscope of 500 times and no cracks can be seen,so the workpiece can achieve the mirror highlight effect.

Suitable for milling machine: CNC carving and milling machine

Application: cutting and processing of acrylic and aluminum material

Features: high hardness, good heat resistance, good wear resistance

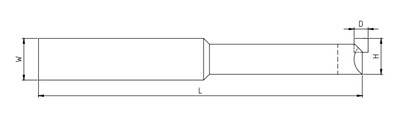

MCD 1.5x3.4x0.6thickness

This is MCD tools size of D1.0xH2.5

|

No. |

Specification(mm) |

W |

H |

D |

|

|

Cut aluminium |

Φ6.0x3.0Hx90°x6D |

6 |

6 |

3 |

90° |

|

Φ1.0x1.0Hx180°x6D |

6 |

1 |

1 |

180° |

|

|

Φ1.5x1.0Hx180°x6D |

6 |

1.5 |

1 |

180° |

|

|

Φ2.0x1.0Hx180°x6D |

6 |

2 |

1 |

180° |

|

|

Φ2.5x3.0Hx180°x6D |

6 |

2.5 |

3 |

180° |

|

|

Φ3.0x3.0Hx180°x6D |

6 |

3 |

3 |

180° |

|

|

Φ4.0x3.0Hx180°x6D |

6 |

4 |

3 |

180° |

|

|

Φ5.0x3.0Hx180°x6D |

6 |

5 |

3 |

180° |

|

|

Φ6.0x3.0Hx180°x6D |

6 |

6 |

3 |

180° |

|

|

Φ8.0x3.0Hx180°x6D |

8 |

8 |

3 |

180° |

|

|

Φ12x3.0Hx180°x6D |

12 |

12 |

3 |

180° |

|

|

Cut acrylic sheets |

Φ1.0x1.0Hx180°x6D |

6 |

1 |

1 |

180° |

|

Φ1.5x1.0Hx180°x6D |

6 |

1.5 |

1 |

180° |

|

|

Φ2.0x1.0Hx180°x6D |

6 |

2 |

1 |

180° |

|

|

Φ2.5x3.0Hx180°x6D |

6 |

2.5 |

3 |

180° |

|

|

Φ3.0x3.0Hx180°x6D |

6 |

3 |

3 |

180° |

|

|

Φ4.0x3.0Hx180°x6D |

6 |

4 |

3 |

180° |

|

|

Φ5.0x3.0Hx180°x6D |

6 |

5 |

3 |

180° |

|

|

Φ6.0x3.0Hx180°x6D |

6 |

6 |

3 |

180° |

|

|

Φ8.0x3.0Hx180°x6D |

8 |

8 |

3 |

180° |

|

|

Φ12x3.0Hx180°x6D |

12 |

12 |

3 |

180° |

|

|

Other sizes can also be customized according to the drawings |

|||||

<< :What are the problems of reamer reaming and how to solve them?

<< :Application research of aluminum alloy in automotive lightweight field

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088