Diamond has a thermal conductivity of 2000 W/m·K at room temperature and is widely regarded as one of the future solutions for enhancing the heat dissipation capacity of semiconductor devices. Whether it is single-crystal diamond or polycrystalline diamond, its thermal conductivity is much greater than that of other substrate materials, making it a superior alternative to other heat dissipation substrate materials.

Ultra-high thermal conductivity: The thermal conductivity of single-crystal diamond is as high as 2000 W/(m·K), which is more than five times that of traditional heat dissipation materials such as copper and aluminum.

Excellent insulation performance: The resistivity of single-crystal diamond is as high as 1016 Ω·cm, effectively avoiding electromagnetic interference and ensuring the stable operation of electronic devices.

Stable chemical properties: Single-crystal diamond is resistant to high temperatures and corrosion, and can work stably for a long time in harsh environments.

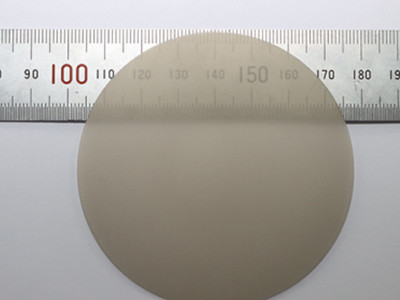

Thinness design: The single-crystal diamond heat sink of Zhengshi Technology has a thickness of only 0.5 mm, meeting the requirements for the thin design of electronic devices such as smart phones and tablets.

AI Data Center Cooling

The power consumption of a single A1 server cabinet has jumped from 30KW to 100KW, with GPU chips becoming the main heat source. By integrating diamond heat sink sheets into the chip packaging, the maximum junction temperature of the chip can be reduced by 24.1°C, and thermal resistance decreased by 28.59%.

5G/6G Communication Base Stations

The heat flux density of 5G base station RF chips exceeds 300 W/cm². Diamond heat sink sheets, as the core thermal management material for power amplifier modules, can lower the base station chip temperature by 30%, ensuring signal transmission stability.

High-Performance Computing and Third-Generation Semiconductors

By directly depositing diamond films on the chip surface or integrating them into 2.5D/3D packaging, the thermal accumulation effect caused by chip stacking can be mitigated. This technology has been widely applied in fields such as power modules for new energy vehicles and deep ultraviolet LED packaging.

Thermal Management in Aerospace

Effectively manage the temperature of onboard equipment to ensure normal operation.

High-Speed Train Brake Systems

The application of diamond thermal materials can improve the heat dissipation efficiency of brake discs, reduce thermal degradation, and enhance the reliability and service life of the braking system.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088