Introduction of PCD Reamers

PCD reamer is supported by carbide or steel matrix, and welded with polycrystalline diamond composite sheet at the cutting edge to form a high-hardness cutting edge. It can be processed efficiently by laser or precision grinding to achieve the required geometric shape. PCD reamer has high hardness, high wear resistance and excellent processing accuracy due to the superhardness of diamond (hardness 8000-10000HV). It is suitable for high-efficiency, precision hole reaming and through-hole tools for non-ferrous metals, composite materials and other high-hardness, high-wear-resistant and difficult-to-process materials.

Customer case of External Grinding PCD Reamers

Our client, a precision cutting tool manufacturer, was seeking to optimize the outer diameter grinding of six-flute PCD reamers, which feature a combination of PCD cutting edges and tungsten carbide shanks. The grinding process involved intermittent cutting with a stock allowance of 0.05mm, and a critical requirement for the edge chipping to be no more than 0.02mm.

PCD Reamers Grinding Wheel Specification:

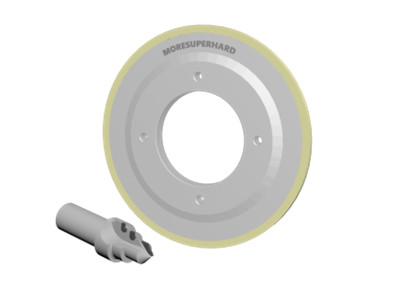

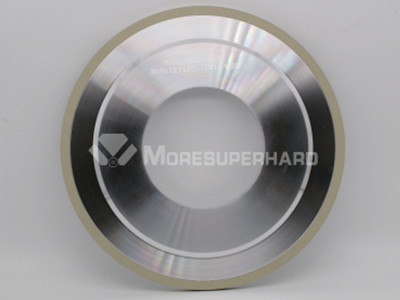

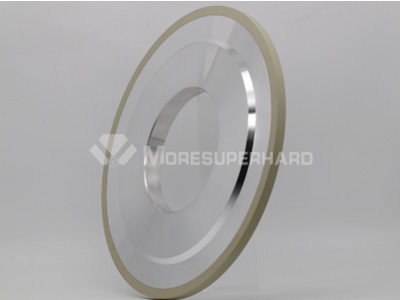

Type: Ceramic Bond Diamond Wheel

Model: 3A1

Grit Size: 1500 mesh

Outer Diameter: 350 mm

Structure: One-piece ring-pressed abrasive layer

External Grinding Wheel Test Results & Observations

Performance on PCD Edge: The ceramic bond diamond wheel successfully met the stringent edge quality requirement during the initial stage of grinding the PCD layer.

Issue on Carbide Shank: During the second stage—transitioning into the tungsten carbide section—an abnormal noise was detected, indicating instability. The root cause was traced to excessive hardness of the grinding wheel when engaging with the denser carbide material.

PCD Reamers Grinding Technical Insights:

PCD vs. Carbide Composition: While our ceramic bond wheels perform exceptionally well on PCD layers, tools with a significant tungsten carbide portion pose additional challenges. Harder wheels that excel on PCD can struggle with heat dissipation and chip evacuation on carbide, leading to burning, loading, and noise.

Features of Moresuperhard Cylindrical Grinding Wheel for PCD Reamers

Our ceramic diamond wheels are manufactured with a one-piece ring-pressed abrasive layer, as opposed to segmented and bonded types.

This advanced design ensures: Superior dimensional stability due to higher sintering and temperature control standards

Lower risk of chipping and burn thanks to consistent density and shrinkage control Enhanced edge quality and surface finish

Moresuperhar Grinding Solution & Optimization for PCD Reamers

To address the instability during carbide grinding, we proposed and are now testing a slightly softer bond formula paired with a coarser grit size. This combination is expected to improve chip clearance and reduce grinding force, leading to a more stable and cooler cutting environment, especially in the carbide section.

<< :Analysis of Common Problems in PCD Tool Grinding

<< :Diamond wafer: the future star of the fourth-generation semiconductor materials

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088