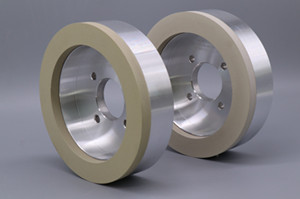

The key to the quality of pcd tool‘s edge in the choice of vitrified bond diamond grinding wheel particle size. The fin grit can processing fine cutting edge chipping but with the lower the grinding efficiency. So the PCD cutting tool sharpening process can be divided into three processing stages: coarse, fine, and super fine according to the accuracy, application, or failure degree of the cutting edge of the tool.

1. According to the accuracy and purpose of the cutting edge

|

No |

Cutting Edge Precision |

Grit |

Purpose |

|

A. Coarse |

0.05mm |

230/270#~320/400# |

Rough machining |

|

B. semi-finishing |

0.02mm |

M20~M40 |

semi-finishing |

|

C. finishing |

0.005mm |

M5~M10 |

finishing |

2.According to the degree of blade failure (re-grinding tools)

|

No |

Cutting Edge Precision |

Grit |

Purpose |

|

A. Coarse |

cutting blade damage 0.5mm |

230/270#~320/400# |

or electrical machining |

|

B. semi-finishing |

cutting edge collapse 0.3mm |

M20~M40 |

|

|

C. finishing |

cutting edge wear 0.1mm |

M5~M10 |

|

In order to ensure the quality of the cutting edge and improve the grinding efficiency, the clearance angle can be divided into large relief angle and small relief angle.

Use coarse-grit grinding wheel to first grind the large relief angle because the contact surface has a large grinding force and the grinding efficiency is high; then use fine-grit grinding wheel to sharpen the small relief angle and control the width of the small relief angle to about 0.1~0.3mm , Good quality of small sharpening of contact surface.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088