Characteristics of CFRP (carbon fiber reinforced composite ) Materials

Carbon fiber is a fiber structural material with a carbon content of more than 90%. It has many characteristics such as low density, high specific strength, and high specific modulus. At the same weight, its tensile strength can reach more than 9 times that of steel, aluminum alloy, and titanium alloy, and its elastic modulus can reach more than 4 times that of steel, aluminum alloy, and titanium alloy. These advantages make carbon fiber an ideal choice for lightweight aerospace vehicles.

Difficulties in processing CFRP Materials

In order to ensure processing efficiency, carbon fiber plates and carbon fiber tubes are usually processed at a higher tool speed. At the same time, due to the heterogeneity of carbon fiber composite materials, carbon fiber and resin act alternately on the tool cutting edge at a higher cutting line speed during processing. The highly hard and wear-resistant carbon fiber has a severe abrasive effect on the tool, causing high temperature in the cutting area. The resin with poor thermal conductivity concentrates heat in a small area near the tool cutting edge, causing serious wear on the tool back face.

Severe tool wear affects the shape, dimensional accuracy and surface quality of the processed product. The low tool life leads to frequent replacement and sharpening, which also increases the processing cost of composite materials.

Advantages of PCD tools in processing carbon fiber composites

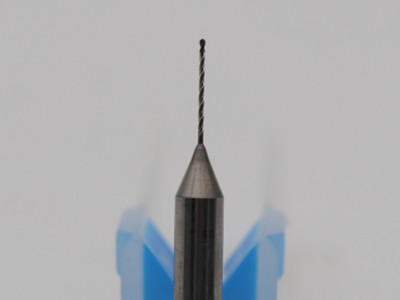

The main difficulties in processing carbon fiber composites are their high hardness, high abrasiveness and unevenness, and the characteristics of PCD tools make them outstanding in solving these problems.

1. Extend cutting tool life

The carbon fibers in carbon fiber composites have high hardness and high abrasiveness, which easily cause traditional tools to wear quickly. The extremely high hardness and wear resistance of PCD tools enable them to maintain a longer service life when processing carbon fiber, reduce the frequency of tool replacement, and improve production efficiency.

2. Improve processing quality

The sharp edge and low friction coefficient of PCD tools enable high-quality cutting when processing carbon fiber. The sharpness of the tool edge reduces the tearing and delamination of the material, thereby improving the finish and overall quality of the machined surface. In addition, the good thermal conductivity of PCD tools also helps to maintain the temperature of the cutting zone stable, reduce thermal deformation, and improve processing accuracy.

3. Reduce cutting force

When processing carbon fiber composites, PCD tools can significantly reduce cutting force due to their low friction coefficient. This not only helps reduce the load on the machine tool and extend the life of the machine tool, but also reduces cutting vibration and improves processing stability and precision.

4. Adapt to efficient processing

The wear resistance and thermal stability of PCD tools enable them to work stably at high speeds and high feed rates, adapting to the needs of efficient processing. This is especially important for mass production and high-precision parts processing.

PCD tools are widely used in the processing of carbon fiber composite materials, covering milling, drilling, turning, boring, cutting, chamfering, slotting and grinding. Its excellent performance enables it to cope with various challenges in the processing of carbon fiber composite materials and ensure high-quality and efficient processing results.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088