Because the PCD tool is produced by high temperature and high pressure synthesis on the hard alloy matrix, irregular shape, uneven surface, cutting edge collapse or expansion is easy to cause tool wear or damage, reduce the tool life. The results show that the higher the quality of the cutting edge is, the thinner the knife marks are left at the boundary of the tool geometry reflection area on the workpiece surface, and the higher the surface finish of the workpiece is. Grinding is the key process that affects the use of PCD tool. PCD tool must ensure good edge before processing workpiece, diamond grinding wheel grinding is the most widely used method.

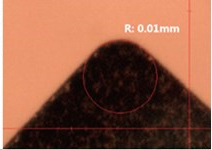

One of the purposes of cutting tool grinding is to obtain cost-effective cutting edge quality, the key role is to choose the grain size of grinding wheel. The finer the grain size of grinding wheel is, the smaller the cutting edge crack is and the lower the grinding efficiency is. Lapping and polishing the surface to mirror Ra<=0.01μm.

According to the precision of cutting edge, purpose classification:

1. Coarse -0.05mm (230/270# - 320/400#) rough processing

2. Fine - 0.02mm (M20-M40) semi-finishing

3. Fine - 0.005mm (M5-M10) finishing

Press the heavy sharpening tool

1. Coarse - cutting edge damage 0.5mm (230/270# - 320/400#)

2. Fine - Cutting edge collapse 0.3mm (M20-M40)

3. Fine - Cutting edge wear 0.1mm (M5-M10)

Control of grinding process:

1. Spindle accuracy is good, generally grinding wheel end runout should be less than or equal to 0.02mm. When the grinding wheel face runout is too large, the grinding wheel discontinuously impacts the cutting edge, which is easy to cause the cutting edge to collapse, and it is difficult to obtain the high-precision cutting edge.

2. The grinding wheel should have good dynamic balance. The unbalance of grinding wheel will lead to the vibration of machine tool, which will affect the quality of cutting edge and machining accuracy.

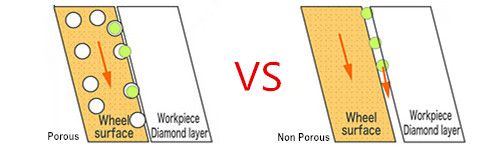

3. Diamond grinding wheel with ceramic bond should be preferred for grinding wheel. In the grinding process, the ceramic bond is easy to crack, so that the abrasive particles get new self-sharpening, so that the grinding process is stable, which is beneficial to improve the precision and efficiency of the machined surface. Its grinding efficiency is twice that of resin binder, and its wear resistance is high, grinding ratio is small, and the service life of grinding wheel is as much as 4 times.

4. Timely pay attention to the grinding wheel cutting edge, and the size of the grinding stone cutting edge should be appropriate. When machining PCD tools with diamond grinding wheel, the grinding wheel will be blocked, passivation, high temperature and rapid wear, resulting in reduced machining speed and vibration marks, noise and burn. Usually choose soft silicon carbide whetstone with 1 ~ 2 finer grain size than the grinding wheel as the cutting edge whetstone.

5. Due to the chemical diffusion between diamond and iron alloy, which accelerates grinding wheel wear, simultaneous grinding of metal and PCD should be avoided as far as possible.

6. The grinding wheel rotation direction must rotate from the front tool to the rear tool surface. From the force on the cutting edge of PCD tool during grinding, when the grinding wheel rotates from the tool front tool to the back tool surface, the grinding force (the sum of tangential and normal force) acts on the cutting edge inward, that is, the tool compression stress, not easy to collapse; On the contrary, it is tensile stress, and the cutting edge is easy to collapse. If the grinding wheel must be reversed due to the tool structure, resin bond grinding wheel is better than metal and ceramic bond grinding wheel.

7. In order to ensure the quality of cutting edge and improve grinding efficiency, the back Angle of the tool can be divided into large back Angle and small back Angle. Coarse grain grinding wheel is used to grind large Angle first, because of large contact surface grinding force and high grinding efficiency; Then use fine grain grinding wheel to grind the small back Angle, and control the width of the edge belt of the small back Angle to about 0.1 ~ 0.3mm, so that the contact surface is small and the grinding quality is good.

8. As far as possible in one clamping to complete the cutting edge of the tool processing.

9. Water based grinding fluid should be preferred as cooling fluid for PCD grinding. Due to the high hardness and poor heat resistance of PCD material, the liquid cooling effect of water-based grinding is better than that of oil-based grinding fluid, which can improve the machining efficiency and edge quality. In addition, in the grinding process, the cooling should be sufficient and the flow should not be cut off, so as to avoid large consumption (oxidation, graphitization) of diamond (grinding wheel, cutting tool) and the cutting edge caused by small or intermittent supply of grinding fluid.

Processing case:

|

Pcd grinding machine |

EWAG EasyGrind |

|

coolant |

emulsion |

|

Workpiece |

PCD insert(Welding, including hard alloy) |

|

grinding parameter |

|

|

Feed |

Vf = 2mm/min |

|

Grinding allowance |

0.3mm |

|

Cutting speed |

Vc=15m/s |

|

Advantage |

|

|

Save 35% time

Life expectancy increased by 20%

Chipping < 10μm |

|

|

|

Rhythm |

Life |

finish |

Grinding situation |

|

Moresuperhard grinding wheel |

25s |

2.5 Thousands of pieces |

Ra≤0.3 |

No rippling,no chipping |

|

Other grinding wheel 1 |

35s |

0.7-0.8 Thousands of pieces |

Ra≤0.4 |

Have rippling,no chipping |

|

Other grinding wheel 2 |

35s |

0.7-0.75 Thousands of pieces |

Ra≤0.4 |

Have rippling,have chipping |

Recommended parameter

Grinding wheel speed---- 10 ~ 26 m/s

Dressing wheel speed---- 6 ~ 26 m/s

Dressing quantity----0.02~0.05mm

Oscillation ---- 10 ~ 120 /min

---EDITOR: Lemon Han

---POST: Doris Hu

<< :The reason of blade wear and treatment measures

<< :Moresuperhard will participate The China cutting tools and Equipments Exhibition-2021

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088