Xu Yannan announced one very exacting news for diamond tools people in the professional wechat group, DIAMOND TOOLS INDUSTRY HIGH-END SUPPLIERS GROUP today, 20200901.

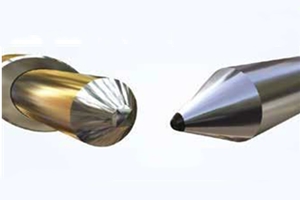

It is my great honor to be here on behalf of Coborn to launch the world premiere of our latest product, PG6 high-precision synthetic diamond/natural diamond/superhard material grinder.The biggest feature of this machine is that it is multi-purpose, which can be used for grinding PCD/ND/SCD/MCD TOOLS at convex/concave and other shapes with high precision, thus greatly improving the production efficiency and reducing the production cost. The Coborn PG6 grinding machine will be exhibited and demonstrated at the 22nd China International Optoelectronic Expo held in Shenzhen on September 9-11, booth No. 5B15.We invite all of you to come and guide us.The following is the product introduction of PG6, please feel free to contact.Best regards!-----Xu Yannan, Director of The Board of Directors and Global Sales Director of Coborn

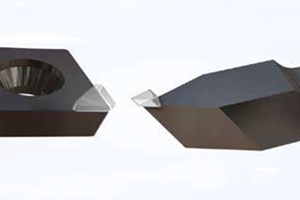

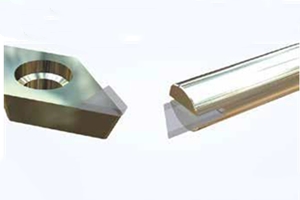

As we know, Coborn is professional at the Mono diamond tools processing solutions, asthmatically, with the quality air bear for the grinder spindle and pivot, so it can precisely machine the low and controlled waviness cutting tools and other complex contour cutting tools, the shape like ellipse, parabolic, hyperbolic and blended radii pro les, also can grind the facetted,coned and radiussed indenters and the concave pro le mono diamond cutting tools.

MORESUPERHARD can supply all the diamond wheels for all series Coborn diamond tools grinding machine.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088