Peripheral grinding size:11A2-D200-H40-W15-X10, W20

2021.5.22 Test Czech D20 custom material formula, hardness 118, density 1.965

Grinding blade: CCGW09T304 element6 010PCD

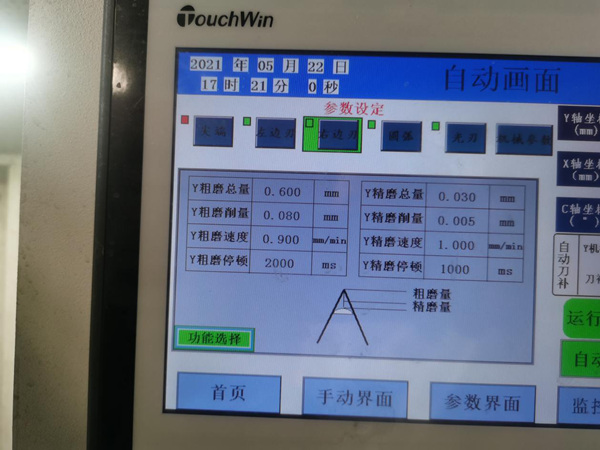

When used on the Taixing grinder, the consumption of the first 7 pieces is almost the same as that of Singapore Airlines. The insert compensation is 0.45, 0.462, and the insert compensation is reduced to 0.23 when entering the stable shedding state. The speed of Sihard can not exceed 1500, and the grinding can not move.

Efficiency of Sihard: 30 tablets 4 hours,while Moresuperhard can reach 50 tablets 4 hours.

The installation of Sihard grinding wheel needs dressing, and there is bouncing.

Moresuperhard almost need no dressing, abrasive falling off stable and 200 times magnification without collapse.

|

Grinding wheel brand |

Thinkness of abrasive layer |

Grinding machine speed

|

Single blade consumes the abrasive layer(mm) |

Grinding time of single blade

|

Number of grinding blades with one piece of grinding wheel

|

|

Moresuperhardd |

10mm |

2200 |

0.023mm |

3min 6s |

400 pieces |

|

Sihard |

11mm |

1500 |

0.045mm |

4min 25s |

200 pieces |

2021-6-4 Dutch conventional formula hardness 105-107, density 1.92

|

Comparison of two formulationns |

Grinding machine speed |

Single blade consumes the abrasive layer(mm) |

grinding time of single blade

|

|

D20 Custom formula |

2200 |

0.023mm |

3min 6s |

|

D20 custom formula |

2100 |

0.032mm |

3min |

Feedback of worker is still D20 customized formula is easy to use, long life, high efficiency, but D20 conventional formula is also better than Sihard, life efficiency is higher than them.

<< :PCD Diamond Dead Center Point For High Precision Machining

<< :How to cutting/grinding/polishing titanium alloy materials

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088