CVD Cutting Tools Grinding Services From Moresuperhard

The advantages and machinable materials of cvd tools

Single crystal diamond tools have the advantages of extremely high hardness and wear resistance, low friction coefficient, high elastic modulus, high thermal conductivity, low thermal expansion coefficient, and low affinity with non-ferrous metals. It can be used for precision machining of non-metallic hard and brittle materials such as graphite, high wear-resistant materials, composite materials, high silicon aluminum alloys and other tough non-ferrous metal materials.

Difficulties in grinding single crystal diamond tools

Single crystal diamond cutting tools have so many advantages, but they often encounter some problems in its production and processing, such as high cost, low efficiency, short life, and insufficient precision.

In response to the above problems, Moao has carried out many grinding experiments and repeatedly adjusted the grinding wheel formula. At present, it has successfully solved grinding problems for many customers.

cvd tools grinding solutions from moresuperhard

1. Start from various aspects to reduce your production cost

Considering the grinding wheel bond, use vitrified bond diamond grinding wheel instead of metal grinding wheel. The vitrified bond grinding wheel has the advantages of high grinding efficiency, long life, good shape retention and high grinding accuracy. At present, it can be successfully replaced in single crystal tool grinding, especially when the tool is roughly ground.

Considering your grinding equipment, single crystal tool is a relatively new tool form in recent years, and many customers have not been able to add special single crystal tool equipment for a while. In this case, Moao can design and produce grinding wheels with matching specifications according to your existing equipment, reducing your cost of introducing equipment and learning new machines.

2.Repeatedly adjust the experiment, the efficiency is significantly improved

In the early stage of production of grinding wheels for grinding single crystal tools, some customers have encountered feedback that the grinding speed of grinding wheels is too slow, and it takes longer to sharpen a knife than others. Knowing this problem, we immediately arranged the technical team to adjust the grinding wheel formula, and made corresponding adjustments according to the customer's problem. At present, the customer's problem has been solved, and the overall efficiency has been improved by 30%.

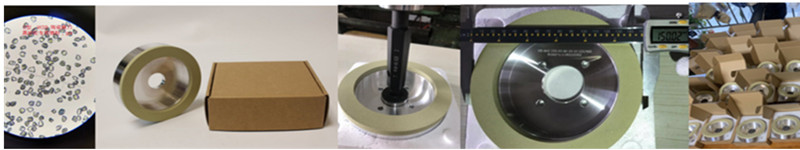

3. Focus on processing quality inspection to ensure grinding accuracy

From raw material selection to abrasive ratio, from grinding wheel pressing to sintering, from machining to finished product quality inspection, Moao always insists on conscientiousness, strictly controls every link, and completely according to customer requirements to ensure the final precision and stability of the finished grinding wheel. , to strive for excellence.

<< :Application Of Synthetic Diamond Materials In The Field Of Cutting Tools

<< :Case Sharing-How moresuperhard help customer solve PCD grinding problems?

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088