Application of PCD cutting tools in woodworking industry

PCD tools are the most representative and widely used type of diamond tools in mechanical processing. Currently, about 30% of PCD tools are used for wood processing. PCD cutting tools can process all wood from natural wood to particleboard, medium and high density fiberboard, but its main application is the processing of materials that can solve high processing intensity requirements, such as laminate flooring.

Characteristics of PCD Cutting Tools

Compared with carbide tools, PCD tools have 3 to 4 times the hardness and more than 100 times the wear resistance. Therefore, PCD tools have extremely high hardness and wear resistance. At the same time, the thermal conductivity is also very good, the thermal expansion coefficient is low, and no large thermal deformation occurs during cutting. Therefore, the service life is long, about 10 to 300 times that of carbide tools. The cutting edge of PCD tools is very sharp, the arc radius of the cutting edge is less than 4㎛, and it can perform thin cutting and finishing.

Hoe to choose PCD cutting tools?

The PCD composite blade is composed of a carbide base, an intermediate zirconium layer, and a diamond particle layer with cobalt or nickel added, and is sintered under ultra-high temperature and ultra-high pressure conditions. The total thickness is approximately 2 to 8 mm. When processing, PCD cutting tools of different brands should be selected according to different materials, rather than simply pursuing high hardness and wear resistance.

Reasonable selection of PCD particle size

The PCD composite blade is composed of a carbide base, an intermediate zirconium layer, and a diamond particle layer with cobalt or nickel added, and is sintered under ultra-high temperature and ultra-high pressure conditions. The total thickness is approximately 2 to 8 mm. When processing, PCD cutting tools of different brands should be selected according to different materials, rather than simply pursuing high hardness and wear resistance.

Coarse-grained PCD tools are relatively more wear-resistant but prone to chipping. Fine-grained PCD can sharpen higher-quality cutting edges, thereby obtaining better surface processing quality. Therefore, finishing or super-finishing tools are required. , you should choose fine-grained PCD cutting tools, which have high strength, good toughness and good impact resistance.

| Grainsize | characteristics | applications |

| 25μm | Has good wear resistance, electrical conductivity, and high impact resistance | Suitable for PCD cutting tools manufactured by electrical machining technology, such as wood, aluminum saws and composite materials. |

| 10μm | Excellent EDM performance with both wear resistance and impact resistance | It is suitable for processing copper, aluminum, aviation composite materials, wood, plastics and other materials, and has a wide range of applications. |

| 2μm | Fine grain size. Has high toughness, good wear resistance and electrical machinability | Used in 3C industry, low silicon aluminum alloy processing (electronic products, computers, mobile phones, etc.). |

PCD cutting tools and wood material processing

In recent years, the development of artificial boards such as plywood, particleboard and composite flooring has accelerated the demand for super-hard tools in the wood industry. PCD tools include two major categories, namely PCD saw blades and PCD formed woodworking milling cutters.

PCD saw blades are made by welding PCD blade blanks to the saw blade base and grinding them. Its structure is similar to carbide saw blades. Most of the current wood processing companies use carbide saw blades. However, when cutting wood-based panels or veneers on fast cutting equipment such as sliding table saws and electronic cutting saws, only PCD saw blades can meet the wear resistance requirements. sexual requirements.

PCD forming woodworking milling cutters include trimming knives, groove knives, furniture forming knives, etc. used for processing the Al2O3 layer of laminate flooring. During processing, the shape of the tool is directly reflected on the wood being processed. Compared with ordinary woodworking forming milling cutters, PCD woodworking forming milling cutters have an increased diameter, an increased number of teeth, and an increased number of revolutions, which can effectively improve milling accuracy. The Al2O3 particles contained in the wear-resistant paper for laminate flooring are second only to PCD in hardness, so currently they can only be processed with PCD tools.

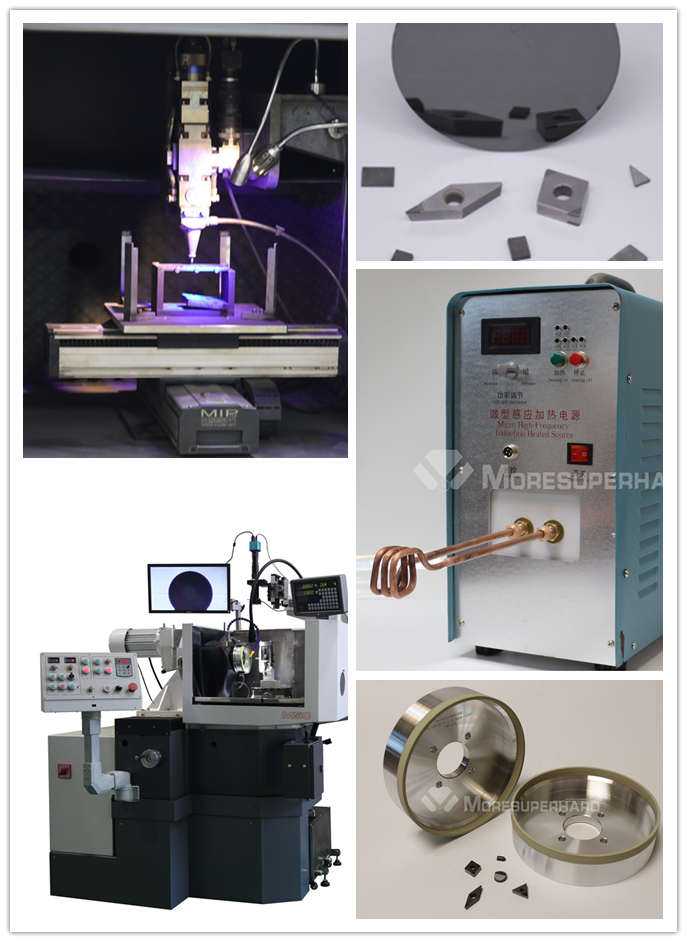

Moresuperhard provide full line of products for processing PCD woodworking tools

PCD blanks,PCD laser cutting machine,vitrified diamond grinding wheel for grinding PCD saw blades and PCD milling cutter,PCD grinding machine and dressing tools for vitrified diamond grinding wheel

Moresuperhard have serviced many customers from PCD tools industry.Therefor ,Moresuperhard have rich experience in grinding various PCD cutting tools.If you need any problems about grinding PCD tools,Please contact us freely.

<< :Research on PCD Micro Drill Tool Manufacturing Technology

<< :How to grind single crystal diamond tools with ordinary grinder?

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088