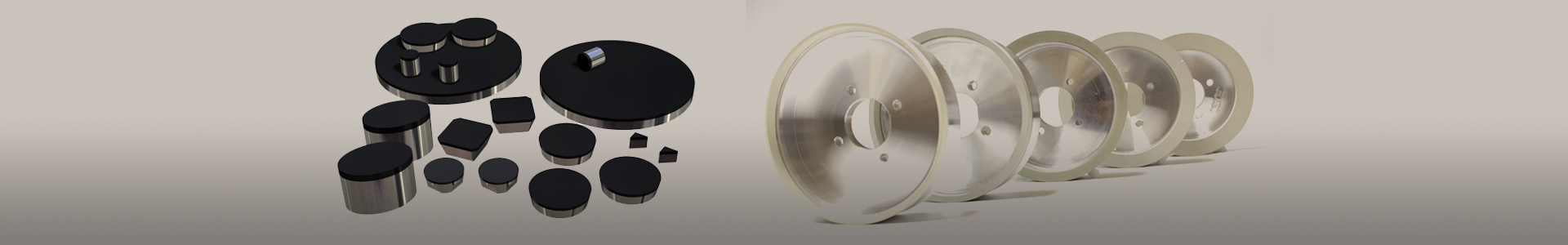

Super-Fine Polycrystalline Diamond PCD Blanks Tips

PCD cutting tool blanks that diameter can reach 62mm

Size of pcd blanks: 2μm,5μm、10μm , 25μm ,50μm,60μm,100μm,120μm

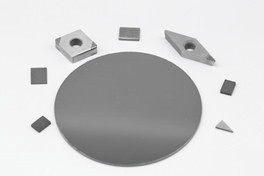

Type: Triangle, Cylindrical, Square, Round, etc

Applications of PCD Tool Blanks

PCD blanks for cutting tools

Woodworking industry;Metalworking industry: Automobile, Aerospace, etc.

Electronic industry (3C); Building materials industry

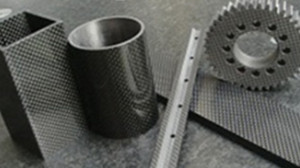

processing carbon fiber reinforced polymer (CFRP) and graphite

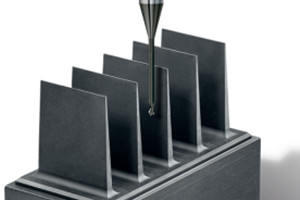

PCD blanks for wear parts

PCD Dead Center Points; centerless grinder bracket

PCD wear-resistant bearing;PCD dressing pen

PCD probe material for grinding machine

How PCD blanks is manufactured

PCD blanks is mainly used in tooling industry for machining non-ferrous metals, composite materials, and wear resistant parts. More SuperHard PCD cutting tool blanks are produced by sintering selected quality diamond particles at high pressure and high temperature, and consist of diamond layer and tungsten carbide substrate.

More Super Hard PCD cutting tool blanks in the size of 5μm、10μm and 25μm can be used in super-fine processing and fine. They are applicable to the processing of non-metal materials as wood, ceramic, intensified planks and non-ferrous material as copper and aluminum. We can supply all kinds of PCD cutting tool blanks that diameter can reach 62mm.

The Application of PCD Cutting Tool Blanks

PCD cutting tool blanks are widely used in various industries

1.Woodworking industry

Moresuperhard PCD cutting tool blanks fine micron series are suitable for processing solid wood, bamboo, plastic; middle grain sizes are good for universal applications for chipboard, wood composite, MDF, laminate flooring, etc.; The mixed microns and rough micron series are mainly for HPL veneer floor, PVC flooring board, MDF/HDF, and reinforced particle panels.

2. Metalworking industry: Automobile, Aerospace

Many grades of Moresuperhard PCD cutting tool blanks are good for tooling various materials in automobile, aerospace industries.

Our sub-micron PCD is mainly for low Si content alloys to obtain perfect processing surface. The fine micron PCD series are for processing low Si content Al alloys, copper & copper alloys. The middle microns are mainly for <14% Si/Al alloys work pieces. The mixed microns and rough microns are good for tooling >14% Si/Al alloys work pieces, cast iron, carbide, CFRP, titanium and metal matrix composites, etc.

3. Electronic industry (3C)

Moresuperhard PCD products in medium fine grain sizes are also applicable for processing mobile phone frame, key, electronic circuit boards, etc., which require better surface finish.

4. Building materials industry

Moresuperhard PCD product in medium coarse grain sizes are also widely used for processing different materials in building & constructing industry, such as graphite, stone, carbon fiber composite materials, etc., which require higher wear resistance tools.

5.Processing carbon fiber reinforced polymers(CFRP)

Moresuperhard provide PCD blanks for cutting tools that used for processing CFRP .CFRP is wilding used in aerospace industry.Using PCD tools processing CFRP can greatly improve the surface quality of carbon fiber reinforced polymers (CFRP), and can promote the use of turning instead of grinding to improve production efficiency. PCD blanks is an ideal materials for processing CFRP.

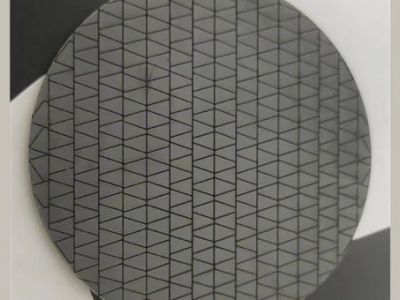

6.50μm PCD blanks for processing graphite

New products of 50μm pcd blanks for pcd cutting tools.It has extremely high wear resistance and very long service life.Moresuperhard help customer solve the problems of pcd cutting tools wear too fast.If you need a economic solutions for processing graphite,please try this new kind of PCD blanks.

Application of PCD blanks in wear-resistant field

1.PCD dead center points 2.PCD wear-resistant bearing

3.PCD probe material for grinding machine 4.PCD dresser

Specifications of PCD Cutting Tool Blank

|

Shape |

Product No |

Angle(A) |

Diameter(D) |

Thickness(T) |

|

Rounds |

R360/8.0 |

360 |

8.0 |

1.6/2.0/3.2 |

|

R360/13.2 |

360 |

13.2 |

1.6/2.0/3.2 |

|

|

R360/30.0 |

360 |

30.0 |

1.6/2.0/3.2 |

|

|

R360/38.0 |

360 |

38.0 |

1.6/2.0/3.2 |

|

|

R360/44.0 |

360 |

44.0 |

1.6/2.0/3.2 |

|

|

R360/51.0 |

360 |

51.0 |

1.6/2.0/3.2 |

|

|

R360/58.0 |

360 |

58.0 |

1.6/2.0/3.2 |

|

|

R360/60.0 |

360 |

60.0 |

1.6/2.0/3.2 |

|

|

Shape |

Product No |

Angle(A) |

Diameter(D) |

Thickness(T) |

|

Half Rounds |

R180/8.0 |

180 |

8.0 |

1.6/2.0/3.2 |

|

R180/13.2 |

180 |

13.2 |

1.6/2.0/3.2 |

|

|

R180/30.0 |

180 |

30.0 |

1.6/2.0/3.2 |

|

|

R180/38.0 |

180 |

38.0 |

1.6/2.0/3.2 |

|

|

R180/44.0 |

180 |

44.0 |

1.6/2.0/3.2 |

|

|

R180/51.0 |

180 |

51.0 |

1.6/2.0/3.2 |

|

|

Shape |

Product No |

Angle(A) |

Leg(L) |

Thickness(T) |

|

Triangles

|

T35/3.8 |

35 |

3.8 |

1.6/2.0/3.2 |

|

T35/4.5 |

35 |

4.5 |

1.6/2.0/3.2 |

|

|

T35/5.0 |

35 |

5.0 |

1.6/2.0/3.2 |

|

|

T35/7.0 |

35 |

7.0 |

1.6/2.0/3.2 |

|

|

T35/9.0 |

35 |

9.0 |

1.6/2.0/3.2 |

|

|

T45/4.0 |

45 |

4.0 |

1.6/2.0/3.2 |

|

|

T45/5.0 |

45 |

5.0 |

1.6/2.0/3.2 |

|

|

T45/6.2 |

45 |

6.2 |

1.6/2.0/3.2 |

|

|

T55/4.0 |

55 |

4.0 |

1.6/2.0/3.2 |

|

|

T55/5.0 |

55 |

5.0 |

1.6/2.0/3.2 |

|

|

T55/7.0 |

55 |

7.0 |

1.6/2.0/3.2 |

|

|

T60/3.0 |

60 |

3.0 |

1.6/2.0/3.2 |

|

|

T60/4.0 |

60 |

4.0 |

1.6/2.0/3.2 |

|

|

T60/5.0 |

60 |

5.0 |

1.6/2.0/3.2 |

|

| T60/6.5 |

60 |

6.5 |

1.6/2.0/3.2 |

|

|

T60/7.0 |

60 |

7.0 |

1.6/2.0/3.2 |

|

|

T60/9.5 |

60 |

9.5 |

1.6/2.0/3.2 |

|

|

T90/3.0 |

90 |

3.0 |

1.6/2.0/3.2 |

|

|

T90/4.0 |

90 |

4.0 |

1.6/2.0/3.2 |

|

|

T90/5.0 |

90 |

5.0 |

1.6/2.0/3.2 |

|

|

T90/6.5 |

90 |

6.5 |

1.6/2.0/3.2 |

|

|

T90/7.5 |

90 |

7.5 |

1.6/2.0/3.2 |

|

|

T90/9.5 |

90 |

9.5 |

1.6/2.0/3.2 |

|

|

Shape |

Product No |

Length(L) |

Width(W) |

Thickness(T) |

|

Rectangle

|

L3.5/3.0 |

3.5 |

3.0 |

1.6/2.0/3.2 |

|

L4.0/2.5 |

4.0 |

2.5 |

1.6/2.0/3.2 |

|

|

L5.0/2.0 |

5.0 |

2.0 |

1.6/2.0/3.2 |

|

|

L5.0/2.5 |

5.0 |

2.5 |

1.6/2.0/3.2 |

|

|

L5.0/3.5 |

5.0 |

3.5 |

1.6/2.0/3.2 |

|

|

L5.0/4.0 |

5.0 |

4.0 |

1.6/2.0/3.2 |

|

|

L6.0/3.5 |

6.0 |

3.5 |

1.6/2.0/3.2 |

|

|

L6.0/4.3 |

6.0 |

4.3 |

1.6/2.0/3.2 |

|

|

L6.0/4.5 |

6.0 |

4.5 |

1.6/2.0/3.2 |

|

|

L6.0/5.0 |

6.0 |

5.0 |

1.6/2.0/3.2 |

|

|

L7.0/3.0 |

7.0 |

3.0 |

1.6/2.0/3.2 |

|

|

L8.0/2.0 |

8.0 |

2.0 |

1.6/2.0/3.2 |

|

|

L10.0/3.0 |

10.0 |

3.0 |

1.6/2.0/3.2 |

|

|

L11.0/2.5 |

11.0 |

2.5 |

1.6/2.0/3.2 |

|

|

L12.0/3.0 |

12.0 |

3.0 |

1.6/2.0/3.2 |

|

|

L13.0/3.0 |

13.0 |

3.0 |

1.6/2.0/3.2 |

|

|

L20.0/20.0 |

20.0 |

20.0 |

1.6/2.0/3.2 |

|

|

L25.0/3.0 |

25.0 |

3.0 |

1.6/2.0/3.2 |

The Advantage of PCD Cutting Tool Blanks

- Super high hardness

- Very good wear-resistance

- Long working life (50-250 times longer compare to carbide cutting tools)

- Superior finished surface of workpiece

- Ideal tools for high precision machining

- High material removal rate

- Multiple shapes achieved easily with laser cut

3.PCD wear-resistant bearing

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088