The roll is the most important production tool of the rolling mill. It is used to complete the basic process of rolling--------plastic deformation of metals. It has a direct relationship with product quality, output, economic benefits, etc., and is a very important factor in the production process. The roll quality will directly affect the mechanical properties, dimensional accuracy, plate shape and surface quality of the product. Secondly, the roll quality will directly affect the production output, such as the increase of the number of roll changes will make the production output directly decreased, how to better and faster processing of the roll is particularly important.

一, Classification and Hardness of Roll

According to the material, they are mainly classified as cast iron roll, cast steel roll, forged steel roll and cemented carbide roll. Their hardness is shown in Table 1:

|

Roll Materials |

Roll Type |

Hardness of Working Layer |

|

Cast Iron |

(infinite) cold cast iron |

HSD60-70 |

|

High Nickel Chrome |

HSD75-85 |

|

|

High Chromium Iron |

HSD70-80 |

|

|

Cast Steel |

High Carbon Semi-Steel |

HSD55-70 |

|

High Chromium Steel |

HSD70-78 |

|

|

High Speed Steel(HSS) |

HSD80-88 |

|

|

Forged Steel |

Alloy Forged Steel

(such as 9Cr2Mo) |

HSD92-105 |

|

Cemented Carbide |

Tungsten Carbide(WC) |

HRA83-87 |

二, Selection of Machining Tools and Machining Parameters

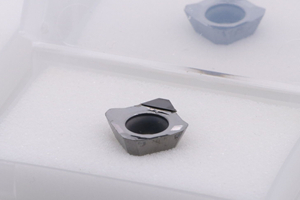

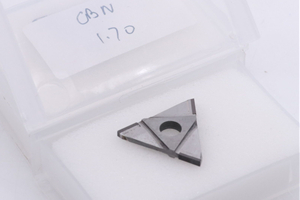

With the improvement and promotion of PCBN product, it has become a reality to select PCBN tools for roller processing. PCBN inserts has higher hardness, abrasion resistance, impact strength and crushing resistance than ceramic inserts.

1. The characteristics of PCBN inserts can match the difficult roll machining characteristics such as roll hardness, strength ...

2. The stability and power of the machine tool and the ability of chip formation are often factors that limit the cutting parameters. Practice has proved that the most economical cutting parameter is high feed and low cut speed.

3. The selection of feed amount is related to the cutting depth, insert size, thickness and shape.

4. The selection of cutting depth, if allowed, should choose a large cutting depth, but pay attention to balance the tool load.

5. The selection of cutting speed, cutting speed is related to the tool distance path, the hardness of the material, strength. Generally choose medium and low speed. If the workpiece speed is high, the vibration occurs because of the centrifugal force of the uniformity of workpiece structure and deformation after heat treatment, which results in machining error and shortens tool life.

It can be seen from the application practice that PCBN inserts from Moresuperhard is 2.38 times more efficient than ZK10UF and 4.5 times more durable than ZK10UF. For large machine tools, if change tools frequently within 30 minutes requires a lots of tool change time, seriously affect production efficiency. The setting of cutting parameters is related to the rigidity of the machine tool, the shape of the workpiece, the material of the workpiece, the structure of the insert, the material of the insert, the geometrical angle of the insert, etc. So choosing the appropriate cutting parameters is an effective way to ensure the normal processing of the roll.

<< :Coated CBN tools for Austempered Ductile Iron cutting

<< :Born for superior surface finishing ---- Single crystal diamond burnishing tool

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088