Grinding trend of automible components

In modern automobile manufacturing, the machining accuracy and surface quality of components are crucial to vehicle performance and durability. In order to meet the ever-increasing production requirements, advanced grinding technologies and materials have emerged. As one of the important innovations, ceramic CBN (cubic boron nitride) grinding wheels are being widely used in various processing links in the automotive industry due to their excellent hardness, thermal stability and wear resistance. This article will discuss the specific application of ceramic CBN grinding wheels in automobile manufacturing, analyze its significant advantages in improving processing efficiency, extending tool life and improving component quality, and look forward to its future development prospects. By gaining an in-depth understanding of this advanced grinding technology, we can better appreciate its critical role in advancing the automotive industry.

What are the key parts of automobiles

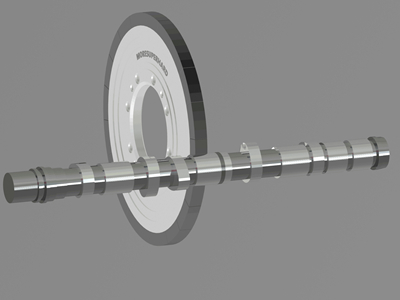

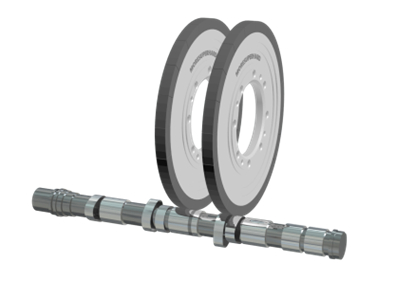

The key components of the automobile include the crankshaft, camshaft and pistons of the engine, the transmission, clutch and drive shaft of the transmission system, the brake discs, brake drums and brake pads of the braking system, the shock absorbers, springs and control arms of the suspension system. The steering gear, steering rod and power steering pump of the steering system, as well as the frame, body panels and bumpers of the body, as well as the battery, generator and starter motor of the electrical system. These parts work together to ensure vehicle performance, safety and reliability.

The parts that need to be ground include the crankshaft and camshaft of the engine, the cylinder block and the cylinder head, the transmission gear and drive shaft of the transmission system, the brake disc and brake drum of the braking system, the brake pad backing plate, and the shock absorption of the suspension system. piston rod and ball joint, steering gear and steering shaft of the steering system, and other contact surfaces such as bearings and seals. Through grinding, these parts can achieve a high degree of precision and finish, thereby improving the overall performance and reliability of the vehicle.

Materials for key automotive parts

Automibles parts mostly use steel because steel has high strength and durability, good processing and welding properties, lower cost and excellent fatigue resistance. In addition, steel is also very easy to reprocess and repair, making it an indispensable primary material in automobile manufacturing.

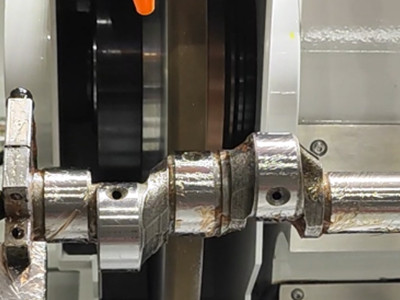

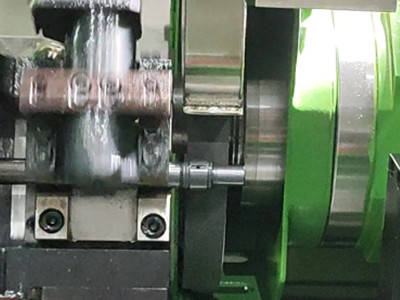

Ceramic CBN grinding wheels for steel crankshaft

Ceramic CBN grinding wheels have the advantages of good thermal stability and good wear resistance. They are not prone to chemical reactions with iron group elements and are suitable for processing hard and tough steel parts. The automotive industry is the main application field of ceramic CBN grinding wheels, especially As for the processing of camshafts and crankshafts, which are key parts of the engine, the processing quality of the camshafts and crankshafts directly affects the power characteristics of the engine; however, due to the large machining allowance and difficulty in grinding, the requirements for grinding accuracy are very high. Processing is relatively difficult. The performance of ordinary corundum abrasive grinding wheels is difficult to adapt to the requirements of efficient processing. Ordinary corundum has low durability and service life and needs to be frequently repaired or replaced, resulting in large amounts of corundum grinding waste and a great impact on the environment. pollution; the hardness of CBN is more than twice that of corundum. CBN grinding wheels meet the requirements of high speed, high efficiency, high precision, low grinding cost and high performance grinding tools, while reducing environmental pollution problems.

CBN grinding wheels commonly used in the automotive industry

1A1,3A1,14A1 grindinding wheels for cylindriacl grinding and surface grinding

1A8 grinding wheels for internal grinding

Moresuperhard company have rich experiences in grinding automible's parts like crackshaft,camshaft etc.If you need CBN grinding wheel,please contact us freely.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088