Development background of peripheral grinding wheel

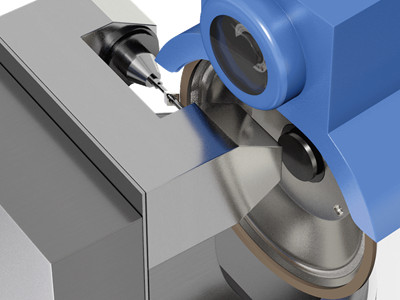

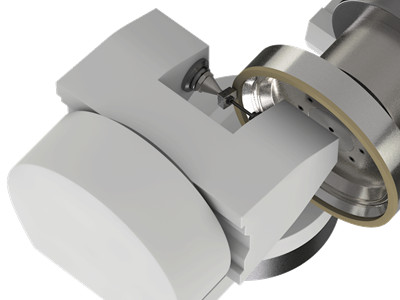

As we all know, indexable inserts, as the mainstay of metal cutting, are in the golden period of development, and customers' quality and requirements for inserts are getting higher and higher. As a result, the market for peripheral grinding wheels used to process carbide, PCD, PCBN, ceramics, metal ceramics and other inserts is also becoming increasingly hot.

Development trend of diamond periphery grinding wheel

✳Superhard material grinding: With the application of emerging materials, peripheral grinding wheels have performed outstandingly in the grinding of superhard materials. The use of superhard materials such as diamond and boron nitride makes the grinding process more efficient and precise.

✳Intelligent grinding system: Introducing artificial intelligence and Internet of Things technologies to achieve real-time monitoring and control of the grinding process. This helps to improve production efficiency, reduce energy consumption, and reduce equipment maintenance costs.

✳Customized solutions: Tool manufacturers are increasingly focusing on providing customers with customized grinding solutions to meet the needs of different industries and applications. Thereby promoting the widespread application of peripheral grinding wheels in multiple fields.

How to choose suitable peripheral grinding wheels?

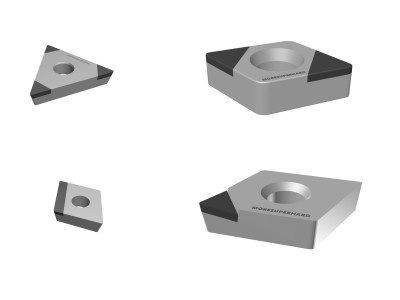

Different types of cutting tools materials determine different formulations and binders of peripheral grinding wheels

① Metal ceramics: brittle and hard, good wear resistance, mostly used for fine processing, suitable for resin diamond peripheral grinding wheels;

② Pure ceramics: hardness of 45°~55°, HRC hard material, suitable for resin/ceramic diamond peripheral grinding wheels;

③ PCD: mostly used for mirror processing of aluminum alloys, suitable for ceramic peripheral diamond grinding wheels;

④ PCBN: hardened materials with a hardness of more than 55° HRC, more common in turning, rarely in milling, suitable for resin/ceramic peripheral grinding wheels.

Dressing solutions for your peripheral grinding wheel

|

Dressing wheel |

Peripheral grinding wheel |

Application |

||||

|

meterial |

characteristic

|

Grain size |

Grinding wheel bond

|

Grinding wheel grain zize |

Grinding method

|

Inscert meterials |

|

Ceramic Alumina Dressing Wheel

|

- Lower hardness - Softer than silicon carbide grinding wheel - no damage to diamond particles during sharpening

- First choice for sharping peripheral grinding wheels

|

120# |

resin |

≥320# |

Peripheral grinding wheel |

Carbide ceramics

cermet |

|

mental |

>600# |

Peripheral grinding wheel |

Carbide

ceramics |

|||

|

vitrified |

>240# |

Peripheral grinding wheel |

carbide

ceramics |

|||

|

320# |

resin |

<320# |

Peripheral grinding wheel |

carbide ceramics cermet

|

||

|

mental |

≤600# |

Peripheral grinding wheel |

carbide,ceramics |

|||

|

vitrified |

≤240# |

Peripheral grinding wheel |

PCBN,PCD |

|||

|

500# |

vitrified |

≤1500# |

Peripheral grinding wheel |

PCBN,PCD |

||

|

Ceramic Silicon Carbide Dressing Wheels

|

- High hardness

- suitable for dressing grinding wheels.

|

80# |

resin |

>120# |

Top and bottom |

carbide,ceramics,cermet |

|

mental |

>150# |

Top and bottom |

carbide,ceramics |

|||

|

200# |

resin |

≥240# |

Peripheral grinding wheel |

carbide,ceramics,cermet |

||

|

mental |

≥320# |

Peripheral grinding wheel |

carbide,ceramics |

|||

.jpg)

Moresuperhard provides customized peripheral grinding wheels that can be adapted to well-known peripheral grinding machines at home and abroad such as Haibao, Tiantong, Hotman, Agathon, Ewag, Wendt, Waida, etc. The size specifications of peripheral grinding wheels can also be customized according to customer needs.

<< :Diamond Frets files for processing guitar frets

<< :Application of ceramic CBN grinding wheels in the automibles industry

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088