In the grinding industry, ceramic diamond double-end grinding discs have attracted much attention for their high efficiency and high precision. In order to help newcomers quickly master the core knowledge in this field, Moresuperhard specially invited Jim, a sales expert in double-end grinding discs, to conduct a systematic training. From basic concepts to practical applications, this training content is full of practical content. Of course, in order to test the learning results, Jim assigned homework to everyone. The students' answers are all very good, which are summarized as follows for everyone to learn and refer to.

Types and application characteristics of grinding disc pills

1. Classification of common pill shapes

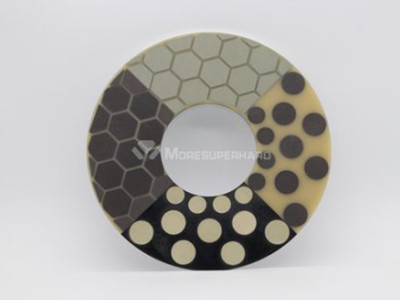

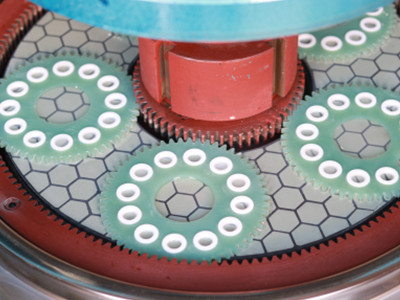

The shapes of ceramic double-end grinding disc pills are varied, mainly including:

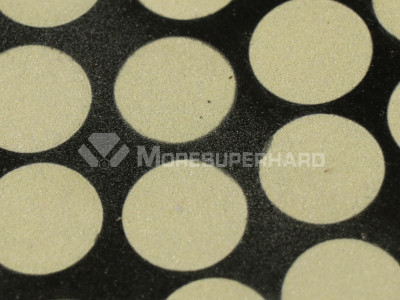

· Round shape

· Regular hexagon shape

· Square shape

· Trapezoid shape

· Fan-shaped

2. Comparison of advantages of common shapes

The most common shapes are round and regular hexagon, which have their own advantages in different scenarios:

Circular pills: more suitable for grinding large diameter workpieces

Regular hexagonal pills: more suitable for grinding small diameter workpieces

Provide suitable grinding discs through information confirmation

1. Workpiece material and abrasive type

· Confirm the workpiece material: different materials such as carbide, mold steel, tungsten steel, glass, ceramics, silicon wafers, etc. have different choices of abrasives.

· Abrasive selection: Diamond (SDC) abrasives are suitable for grinding most materials, and some materials require CBN abrasives or mixed abrasives.

2. Grinding disc specifications and processing parameters

· Basic dimensional specifications such as grinding disc outer diameter, inner hole, abrasive layer thickness, number of water outlets for particle size positioning holes, etc.

· Processing requirements: grinding allowance, finish, and flatness requirements.

3. Customer history of use

· How does the current grinding disc perform? What is the reason for replacement?

· What is the most urgent problem to be solved at present? Grinding disc life problem or grinding efficiency problem.

· Can the grinding disc substrate be provided?

4. Grinding machine matching

· Is the brand of grinding machine used by the customer adaptable?

Why is the grinding disc worn out too quickly?

1. Workpiece factors · Material and size: If the workpiece material is too hard or the size is too large, it will increase the wear of the grinding disc.

2. Grinding disc performance · Improper selection of particle size: Too coarse will lead to uneven surface, and too fine will lead to low grinding efficiency. · Grinding disc formula problem: Soft grinding discs may cause abrasive shedding to accelerate.

3. Processing parameters · Feed amount and speed: Too high parameter settings or too high dressing frequency will directly increase grinding disc loss. · Cooling problem: Insufficient grinding fluid or dry grinding can easily lead to overheating and damage.

4. Operation and maintenance · Inadequate dressing will affect the grinding effect and the life of the grinding disc.

· Operational errors or untimely daily maintenance are also important causes of loss.

Through this training, the trainees not only deepened their understanding of ceramic double-end grinding discs, but also mastered the ability to transform theoretical knowledge into actual sales and services. In the future, Moao will continue to provide more professional training, grow together, and create greater value for customers!

Looking forward to your participation: If you have any questions about ceramic double-end grinding discs, please feel free to leave a message or consult at any time, we will answer you as soon as possible!

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088