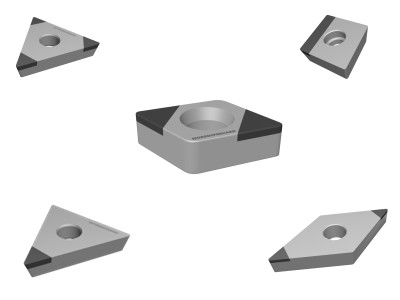

Introduction of Indexable inserts

Indexable inserts are reusable tool inserts that can be turned over or replaced multiple times to extend tool life and reduce processing costs. Such inserts are usually made of high-hardness, high-wear-resistant materials such as cemented carbide (WC-Co), ceramics, cermets, and PCD (polycrystalline diamond)/CBN (Cubic Boron Nitride) etc.

Features of Indexable Inserts

Economical: A single blade contains multiple cutting edges, which can be rotated or flipped for use after the edge is worn, without replacing the entire tool.

Efficient: Simple and fast clamping, reducing tool change time and improving production efficiency.

Wide applicability: Suitable for turning, milling, drilling and other processing processes, and can process a variety of materials, including steel, cast iron, stainless steel and non-metallic materials.

Customized options: A variety of geometric shapes (such as squares, triangles, diamonds), sizes and coating types to meet different processing needs.

Moresuperhard Grinding Wheel for Indexable inserts

Moresuperhard is committed to manufacturing diamond grinding wheels that can grind a variety of materials such as carbide/ceramic/cermet and PCD/PCBN. In addition, the grinding performance of our company's grinding wheels is very good, because the main focus of the design of the grinding wheels is to shorten the production cycle and increase the dressing interval, which can improve the production efficiency of customers while also taking into account the excellent finish and uniform edge of the blade.

Peripheral Grinding Indexable Inserts

1. Shorten production cycle by high feed rate

2. Small blade chipping size after grinding

3. Longer grinding wheel dressing interval

4. Short delivery time: 7-10 working days

Applicable grinders: Agathon, Wendt, Waida, Ewamatic and Ewag, Tiantong, Haibao, Haotman

Choose grinding wheel according to different inserts materials

Resin bond (better polishing effect): carbide tool/ceramic tool/metal

ceramic tool/PCBN tool Ceramic bond (more stable tool size): carbide tool/metal ceramic tool/PCBN tool/PCD tool

Hybrid bond (high efficiency): carbide tool/ceramic tool/metal ceramic tool/metal ceramic tool/PCBN tool

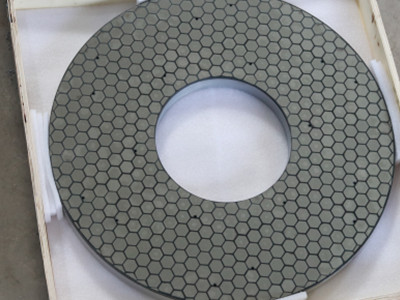

Double Surface Grinding Indexable Inserts

1. Achieve extremely high grinding efficiency through the selection of diamond raw materials and the combination of binders

2. Extend the dressing interval through the self-sharpening of the grinding wheel itself

3. Improve the dimensional stability of both sides of the tool and can be adapted to the grinder

4. The grinding wheel body can be recycled

Applicable grinders: Stahli, Peter Wolters, Wendt WBM, Agathon T&B, SKF, Risheng.

Choose grinding wheels according to different tool materials

Resin bond grinding disc: carbide tool/ceramic tool/metal ceramic tool/PCBN tool

Ceramic bond grinding disc: carbide tool/ceramic tool/metal ceramic tool/PCBN tool/PCD tool

Any questions please contact us freely.

<< :Ceramic Diamond Double-End Grinding Disc Training Sharing

<< :Effect of temperature on the stability of vitrified diamond grinding wheels

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088