Throughout human history, gemstones have always played an important role. Whether used as jewelry, crafts or decorations, gemstones are a shining part of human civilization. To transform raw gemstones into gorgeous works of art requires exquisite processing techniques. In this article, we explore how gemstones are worked, revealing this ancient and mysterious art and skill.

1. Preparation

The first step in working with gemstones is preparation. This includes selecting suitable gemstone raw materials, cleaning and inspecting the gemstones to ensure that their texture and shape meet processing requirements. At the same time, you also need to prepare the corresponding tools and equipment, such as grinding discs, saw blades, grinders, etc.

2. Cutting and sawing

Cutting is one of the key steps in gemstone processing. Cut the raw stone into the desired shape and size by using a saw blade or other cutting tool. During this process, special attention needs to be paid to maintaining the integrity and beauty of the gemstone and ensuring the accuracy and finesse of the cutting.

3. Lapping and Grinding

Polishing and grinding are important steps in processing gemstones, which can make the surface of the gemstone smooth and shiny, and highlight its color and inner beauty. At this stage, it is necessary to use various grinding discs and abrasives with different particle sizes, select according to the hardness and texture of the gemstone, and gradually carry out coarse grinding, medium grinding and fine grinding until the desired effect is achieved.

How to choose gemstone grinding disc?

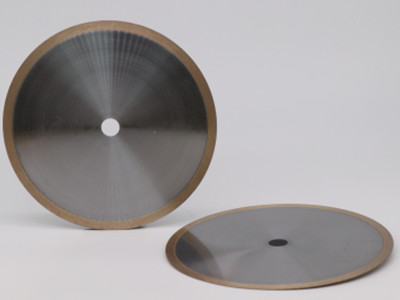

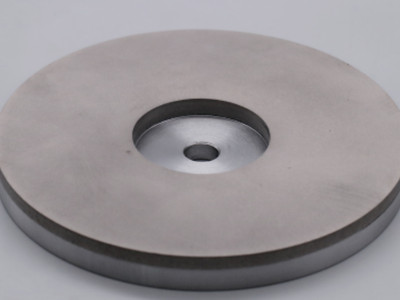

Gemstone grinding discs are usually divided into two main types: resin grinding discs and sintered grinding discs. Resin grinding discs are cheaper, suitable for general processing tasks, and have good self-sharpening properties. Sintered grinding discs are more durable and suitable for tasks requiring higher processing pressures and temperatures, but are generally more expensive.

Comparison of the pros and cons of different grinding discs

| Characteristics | resin diamond grinding disc | Sintered grinding discs |

| Life | short | long |

| Shape Retention | a little good | very good |

| Self-sharpening | very good | a little good |

| Cutting force | weak | strong |

| Processing objects | diamond and gemstone | glass |

Moresuperhard provide resin gemstone grinding disc and sintered diamond grinding discs for grinding gemstone.Resin gem wheel particle size range 200#-15000# andBronze sintered gemstone wheel particle size range 200#-10000#.

4. Polishing and retouching

Polishing and retouching are the final steps in gemstone processing, making the surface of the gemstone smoother and more refined, and enhancing its color and luster. In this process, special polishing tools and polishes are used to achieve the best gloss and transparency on the surface of the gemstone through repeated polishing and polishing.

Processing gemstones is an ancient and mysterious art and skill. It combines science, technology and creativity, and demonstrates human pursuit and exploration of beauty.Moresuperhard hopes that we can provide consumables to make your gem processing more efficient like diamond cutting wheel,diamond grinding disc and diamond polishing paste.

<< :Application of single crystal diamond grinding technology in stylus manufacturing

<< :Why does your grinding wheel fall apart during grinding?

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088