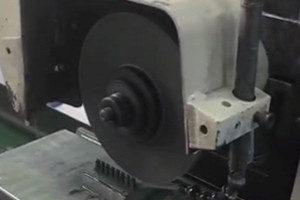

Recently,We received a inquire of vitrified diamond grinding wheel for rough grinding PCD cutting tools.After communicating with the customer, we learned that the grinding wheel used by the customer had broken down and the grinding wheel was hard to dress. Let’s take a look at what causes the grinding wheel to break.

Grinding workpieces:PCD cutting tools

Grinding wheel specifications: vitrified bond diamond grinding wheel 1A1 180D-31.75H-10T-10X 325/400

Grinding process:Rough grinding

Moresuperhard' engineers analyzed the causes of grinding wheel rupture based on the grinding wheel pictures sent by the customer. The summary is as follows:

1.The marking indicates that the grinding wheel was made in July 2023, but the grinding wheel made in summer was not used until winter. The base of the 1A1 parallel grinding wheel is prone to thermal expansion and contraction, causing the grinding wheel to crack.

2.There is obviously no glue stain on the exposed parts of the customer's grinding wheel base. It may be that the grinding wheel was not firmly bonded during production, causing the grinding wheel to crack during use.

3.As for the difficulty of dressing the grinding wheel, one reason is that the grinding wheel formula is too hard, and the other reason is that the diamond concentration is low and the auxiliary materials have many impurities.

Moresuperhard based on the current problems encountered by customers, Moresuperhard provides customers with Moresuperhard's ceramic diamond grinding wheels for trial use, and the grinding efficiency is very high. Perfectly helped the customer solve the problem. Based on this customer’s case, some suggestions for purchasing PCD grinding wheels are summarized.

1.The correct amount of grinding wheels must be stocked. Too many grinding wheels will cause temperature changes and have negative effects during use. Moresuperhard's delivery time is very short, and the delivery time for regular specifications of ceramic diamond grinding wheels is usually 7-10 working days.

2.You get what you pay for.Moresuperhard provides high-quality PCD grinding wheels. The raw materials of ceramic diamond grinding wheels have been screened at all levels and accumulated through many years of experience. Moresuperhard has mature grinding wheel formulas for grinding PCD tools and can provide matching grinding wheel dressing solutions.

<< :Discover the art and techniques of gemstone processing

<< :Four key points that novices in single crystal diamond tool grinding must master

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088