Classfications of glass cutting wheel

There are about three types of cutter head materials for glass cutter wheels.

Natural diamond glass cutter wheel (commonly known as: diamond glass cutting wheel),

artificial diamond glass cutting wheel

carbide glass cutting wheel

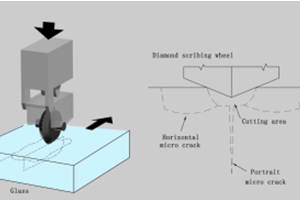

The main part is the cutter head, which is also the key part of the glass cutting wheel, which determines the cutting quality of the scribing wheel. The cutting wheel head has a sharp edge with a relatively large angle .Use a glass cutting wheel to scratch the surface of the glass, and the blade will leave a groove with a sharp bottom on the glass.

Carbide glass cutting wheel Diamond scribing wheel

Applications of diamond glass cutting wheel or pcd glass cuttting wheel

The diamond cutter wheel for glass cutting is mainly suitable for high-precision and high-quality cutting of liquid crystal glass in the electronics industry. It can also cut architectural and automotive glass. It is an ideal substitute for ordinary glass cutters and carbide glass cutter wheels. The diamond cutter wheel has excellent wear resistance and edge sharpness, and the best shape and position accuracy can be achieved through fine grinding. For liquid crystal glass that needs precision cutting, its excellent quality cannot be replaced by alloy cutter wheel.

How to choose diamond glass cutting wheel?

1.High penetration diamond glass cutter wheel

Widely used in high-end LCD panel and substrate glass, touch screen and automotive thin glass cutting, the crack depth is controllable and vertical

2.Micro-tooth diamond glass cutting wheel

Mainly used for ultra-thin TFT panel glass cutting that requires compression testing, the tangent and section are neat and free of damage

3.Standard diamond glass cutting wheel

Suitable for cutting LCD panel and substrate glass, cutting glass of various thickness and hardness for touch screen, automobile, glass production line, glass tube, etc.

4.Composite diamond glass cutting wheel

Used for cutting thin glass below 5mm, such as low-end LCD panel glass, substrate glass, touch screen, etc.

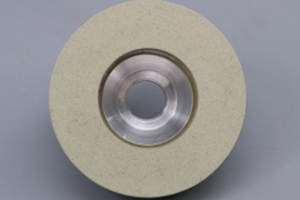

Diamond glass cutter wheel has superior performance but is difficult to process

Moresuperhard have rich experience in grinding diamond materials including diamond cutting tools,polycrystalline diamond wear parts,diamond wire drawing dies and diamond scribing wheel.Moresuperhard have developed vitrified diamond grinding wheel for grinding diamond glass cutting wheel.

Customized formulation of diamond grinding wheel for grinding diamond scribing wheel.High efficient and high precision.Welcome your inquire

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088