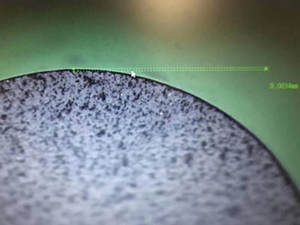

Vitrified (Ceramic) diamond grinding wheel can achieve 3μm PCD tool chipping

With the increasing advancement of industrial technical requirements, the requirements for PCD tool processing in various industries are not limited to stability and high efficiency, but gradually change to high precision and high requirements. For a long time,

Moresuperhard has been aiming to improve the quality of grinding wheels, and to meet the processing requirements of customers as its own responsibility, and insist on continuous exploration and research to make China's best grinding wheels.

Recently, we met a customer who needs to process high-precision chamfering knives. The customer used a ceramic diamond grinding wheel with a particle size of 4000# for grinding on COBORN equipment. At this time, the processed PCD chip was enlarged by 200 times. The microscope measured 8μm, which failed to meet customer needs. After communicating with customers for more details, it was decided to use a particle size of 6000#, and two formulas, soft and hard, were provided for customers to try.

After the customer's test, it is concluded that the PCD is ground with a 6000# ceramic diamond grinding wheel with a grinding particle size of 6000#. The size of the chipping after processing by the two hardness grinding wheels is similar. After magnifying 200 times, the tool chipping is 5μm, and the improvement effect is obvious. question. At the same time, the customer also reported that the grinding wheel stability is very good, and the quality control is very good.

In fact, the current domestic coarse-grained grinding wheel formula and processing technology may not be very different, the quality control and processing technology of the product have been improved, and the size of the chipping after grinding is also similar. The key is to control the consistency and stability of the grinding wheel. Up to now, Moresuperhard coarse-grained grinding wheel has been well received by customers for many times.

Although the coarse-grained grinding wheel has made great progress in China, the quality of the fine-grinding grinding wheel is uneven, and there are still many problems, which are mainly reflected in the poor grinding wheel formula and large grinding chipping, which cannot meet customer requirements. After continuous testing and adjustment, combined with the actual use of customers, the fine-grained grinding wheel of Moresuperhard has been able to meet customer requirements with high precision and has been widely praised.

Moresuperhard has been committed to the research of fine-grained grinding wheels for many years, and has made many breakthroughs in the field of fine-grained grinding. Now the chipping control of fine-grained ceramic diamond grinding wheels has reached the following levels:

W10---10μm

W5---10μm

W3.5---8μm

W2.5---5μm

W1.5---3μm

If you have high-precision PCD tool grinding needs, or encounter PCD tool grinding problems at this stage, welcome to inquire.

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088