Laser-cut PCD-tipped inserts can provide a smooth cutting edge for a mirror-like finish and longer insert life.

Principle of laser cutting PCD

It is a laser beam with very high density of energy star irradiates on the surface of polycrystalline diamond, and part of the light energy is absorbed by the surface and converted into heat energy. The temperature in the local area of the irradiated spot rises rapidly to tens of thousands of degrees, which makes the polycrystalline diamond material locally melt or even vaporize and form a pit.

By comparing the machining principles of WEDM, HSS grinding and laser cutting, the advantages of laser cutting are as follows:

1. Smooth surface finish

At present, when using WEDM or high speed steel disc processing pcd will cause diamond grains will crack, which will destroy the structure and affect the cutting performance of PCD material.

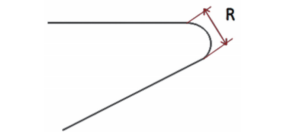

Laser cutting directly acts on the diamond grains and link materials for processing with process high purity and coarse particles character , it can obtain the cutting edge fillet radius<15um, perfect cutting effect without breaking edge.

2. Complicated forms and tight tolerances

The tool used in the rounded edge processing of the iPhone phone shell is the PCD forming tool. It takes 30 minutes when using the ball milling cutter is used for the spindle processing,

After the forming PCD milling cutter is used for processing, every time It only takes 20 seconds. Greatly improve the efficiency and reduce the cost.

3. Smaller cutting radius edge

Laser cutting technology is a non-contact processing technology, cutting quality star is good, the minimum edge radius of the blunt circle can reach between 3-5um.

4. less influence on edge heat.

The principle of laser cutting is to make the workpiece in its focus position by high power density of laser spot irradiation, the instantaneous high temperature of tens of thousands of degrees, the process of instantaneous gasification, the thermal impact of the cutting process is small.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088