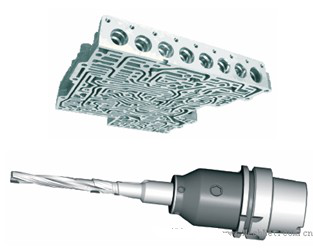

The processing of the sliding valve hole of the automobile automatic transmission valve body is the most demanding station in the whole box hole processing technology. In the common processing of aluminum alloy valve bodies with silicon content between 8% and 16%, MORE usually adopts a combination of two tools: "first rough and then fine processing".

1. Reaming rough processing

Adopt PCD straight groove reaming tools

Its machining speed n=8000r/min, feed rate Fn=0.3mm/min.

The main characteristics of the reaming tool:

1. Good at processing interference holes.

2, finish and guide is very good, so it can ensure high roundness, cylindricity, smoothness requirements.

3, with excellent deburring function, basically do not need special subsequent deburring process.

4, the processing efficiency is usually 3 ~ 8 times of the straight slot tool, so as to directly reduce the customer's equipment and personnel costs.

2. Reaming hole finishing processing

Adopt PCD spiral groove finishing reamer tools

Its machining speed n=10000r/min, feed rate Fn=0.5mm/min.

Adopts the "first rough, then fine" processing scheme, the workpiece processing surface has a very ideal mirror effect, can achieve the surface roughness Ra 0.08 ~ 0.20, and the tool life before grinding can reach 80 thousand holes stably.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088