1. Tool wear has the following types

Mechanical wear, binder wear, reverse transformation (phase change) wear, chemical wear, diffusion wear, adhesive wear, micro-cracking wear, and abnormal wear.

Wear form: The rake face is worn and the flank is worn.

Blunt standard: The average flank wear width VB=0.3mm.

2. PCBN tool Re-grinding examples

Blade Re-grinding is mainly divided into the following processes:

(1) Clean with alcohol cotton.

(2) Measurement:

a. The blade with large chipping and large wear (exceeding the grinding limit) is regarded as unable to be sharpened.

b. Small cracks and small wear are grouped for grinding according to the requirements of the drawings, and the size tolerance of each group of grinding is within 0.05mm.

(3) Grinding: Grinding the worn tools grouped by size.

(4) Detection: measurement with Wangong display instrument.

(5) Packaging: unified packaging according to the detection size.

According to Wangongxian's measurement of the blade size before grinding (PCBN), to formulate grinding standards and grinding plans.

3. Re-grinding plan

1). Determine the grinding limit and scrap standard according to customer requirements;

2). Check whether the blade has large chipping or wear;

3). Develop the grinding drawings and grinding process according to the grinding limits and grinding requirements provided by the customer;

4). According to the requirements of the drawings, divide the blades into groups according to their size and perform batch grinding;

5). Measured by Wangong display instrument, and put it into storage and pack after qualified

4. Re-grinding standards

1). The body of the blade is clean and tidy, free of foreign matter, no cracks or rust on the surface, and no chipping on the blade;

2). The rake and back angles remain unchanged after grinding;

3). The thickness of each blade is consistent;

4). Radial runout tolerance of the cutting edge is 0-0.05mm;

5). The circular runout tolerance of the end face of the blade is 0-0.03mm;

6). Grinding feed: generally 0.002~0.01mm each time.

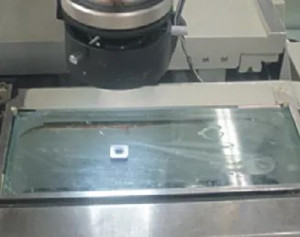

CNC (PCBN) grinder: The manipulator automatically loads and unloads and detects automatically, suitable for mass production of standard blades.

5. matters needing attention before re-grinding

1). First select the grinding wheel with PCBN tool edge rough grinding, and then program the rough opening wear amount (note that the first tool must be self-checked after the first tool is finished, to avoid batch repair or batch scrap).

2). Then select the grinding wheel suitable for the fine grinding of PCBN tool cutting edges, and then program for fine grinding of the cutting edges (note that the center of the tool must be adjusted between the first, second, and each step to avoid errors in the clamping of the manipulator).

3). After finishing grinding, put them into the box for inspection in corresponding groups (be careful to damage the cutting edge when putting in).

4). The tool with chamfering is transferred to the next process for chamfering, and the tool without chamfering is transferred to the final inspection.

The chamfering is mainly on the main cutting edge of the tool, that is, a narrow plane is ground between the flank face of the tool and the rake face of the tool. The chamfering is added to increase the strength of the blade, improve the force and heat dissipation conditions, and improve the durability of the tool. . Especially suitable for hard cutting, such as PCBN (polycrystalline cubic boron nitride) cutting hardened steel, etc.

6. matters needing attention

1). Adjust the dynamic balance of the grinding wheel;

2). Adjust the positioning of the feed;

3). The self-check of the chamfer of the first grinding tool.

a. Whether the chamfering angle is correct;

b. Whether the size of the chamfer is qualified.

The cutting edge of the tool occupies is an important position in the cutting process, and the improvement and improvement of tool performance is of great significance to the cutting process. The technology of cutting tool edge passivation has not attracted enough attention at present. Compared with the development of tool materials, tool structure, tool coating and other technologies, the technology of tool edge passivation is relatively lagging behind. By reasonably passivating the cutting edge of the tool, the tool life and cutting performance can be significantly improved, and the stability of the cutting system can be improved.

7. the advantages of measuring with advanced universal display instruments

1). With powerful image processing software, it can complete complex measurement work. The software data can communicate with CAD to complete surveying and mapping work;

2). The software uses digital image technology to automatically identify the contour boundary of the tool, reduce visual errors and improve operating efficiency;

3). With digital display indexing table and height measuring device, the angle and height are all digitally displayed, intuitive and convenient;

4). The lighting device adopts LED cold light source, the heat is low, the main microscope can be tilted left and right, suitable for the measurement of spiral parts;

Under 60 times magnification optical microscope inspection, it can detect whether the cutting edge of the tool has chipping and whether the dullness is uniform. The cutting edge of the tool is good, and the passivation is uniform, which can improve the processing efficiency of the tool and the quality of the workpiece. This can significantly improve the cutting life and cutting performance of the tool.

<< :PDC cutter for cobalt removal and non-cobalt removal

<< :Advanced processing solutions for aerospace split blisks

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088