The blisk is one of the key parts of aero-engines, and it is usually divided into two types: split type and integral type. The split type blisks are mostly connected with the blades through the wedge-shaped tongue and groove or fir tree-shaped tongue and groove structure. Commonly used in engine fans, compressors and turbines, these complex parts need to have a variety of performance characteristics, so they are required to be processed under the highest possible standards. If you want to effectively produce engine blisks, you must understand and apply the latest and most creative cutting technology.

Power turning

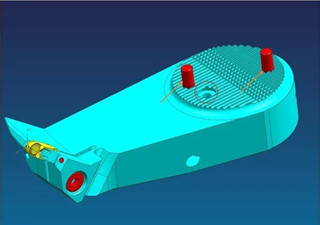

Modular flying tool

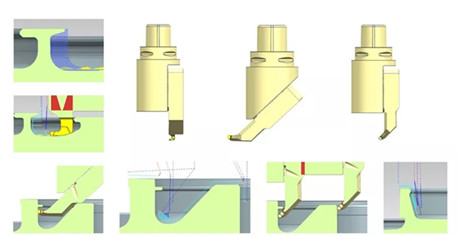

The positioning is performed by the bidirectional vertical V-groove covered with the connecting surface of the tool holder to provide better rigidity. There are also coolant connection holes on the connecting surface, which can be guided to the area as close as possible to the cutting position of the tool tip through the inside of the tool holder, and locked with two bolts (the two red cylindrical parts in the picture above).

The modular flying tool shown in the figure above can use irregular tool holders to realize the processing of interference areas; or use the same tool holder to install on different tool holders to achieve 90° and 45° deflection angles, which can cover More than 80% of the processing area of ??the impeller disk. It is well known that more support can increase the rigidity of the tool tip when processing narrow parts, which is beneficial to the application of higher cutting parameters or making the processing process more stable. This customized modular combination can be freely and flexibly combined to achieve lower usage Cost and process as stable as possible.

Hole processing

-M and -T chipbreaker drill bits

Both of these drills adopt a design that is more suitable for high-temperature resistant materials, optimize the drill point and land, use a larger relief angle, take into account the strength of the tool and the sharpness of the drill point, and make the drilling process more It is light and fast, so that the cutting heat is kept in a low range, and the quality of the processed hole can be improved while achieving a longer tool life, and the burr at the exit can be controlled in a smaller range.

-M chipbreaker drill bit is suitable for high temperature resistant alloy materials;

-T chipbreaker bit is suitable for titanium alloy materials;

<< :Master these Re-grinding techniques to easily realize tool recycling

<< :Analysis of influence of PCD cutting edge strengthening on performance

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088