A cutting tool in metal working can be defined as “any tool that is used to remove metal from the work piece by means of shear deformation”. Frequently, it also refers as a tool bit. In order to perform effective cutting operation, the cutting tool must be made of a material harder than the work material to be cut. Also, the tool must be able to withstand the heat generated during machining process.

The tool must have a specific geometry (known as tool geometry) for effective cutting and smooth surface finish. According to the tool geometry, the cutting tools can be classified into solid cutting tools and carbide tipped tools.

There are two surfaces adjacent to the cutting edge of the tool:

(a) Rake surface.

(b) Flank surface.

(a) Rake Surface:

Rake surface directs the flow of newly formed chip. It is oriented at a certain angle is called the rake angel ‘a’. It is measured relative to the plane perpendicular to the work surface. The rake angle can be positive or negative.

(b) Flank Surface:

The flank surface of the tool provides a clearance between the tool and the newly formed work surface, thus protecting the surface from abrasion which would degrade the finish. This angle between work surface and the flank surface is called the relief or clearance angle.

Types of Cutting Tools:

Various cutting operations require various types of cutting tools. To achieve good surface quality, proper cutting tool selection is very important.

Following are some important parameters to be considered while selecting a cutting tool for particular machining operation:

i. Geometry.

ii. Material to be machined.

iii. Shape and Size of part.

ADVERTISEMENTS:

iv. Type of operation required.

v. Machine tool quality.

vi. Surface finish required.

vii. Holding facility.

viii. Machining parameters such as feed speed and depth of cut selected.

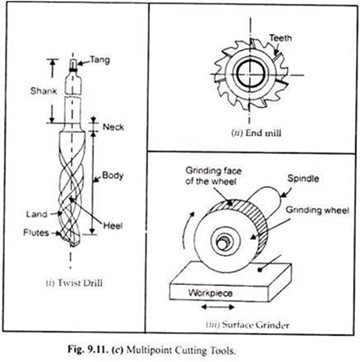

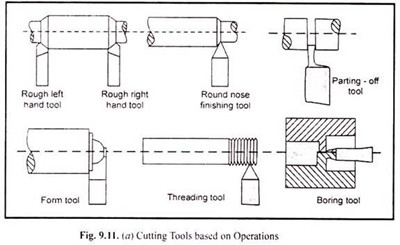

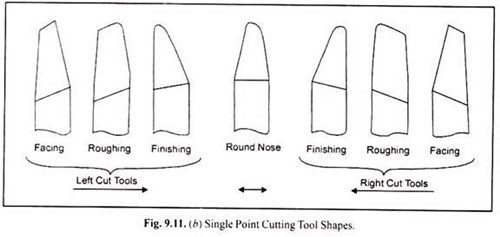

The various types of cutting tools are shown in Fig. 9.11.

The major classifications of cutting tools are following:

(i) According to Construction:

(a) Solid tool.

(b) Carbide tipped tool.

(ii) According to Number of Cutting Edges:

(a) Single point tool.

(b) Multipoint tool.

(c) Formed (Tailor designed) tool.

(iii) According to Shape:

(a) Square.

(b) Circular.

(c) Left hand.

ADVERTISEMENTS:

(d) Right hand

(e) Round nose

(f) Straight nose

(iv) According to Operations:

(a) Turning

(b) Drilling

(c) Threading

(d) Knurling

(e) Boring

(f) Forming

(g) Parting-off

(h) Reaming

(v) According to Type of Cutting Tool Material:

(a) H.S.S.

(b) Carbide

(c) Ceramics

(d) Diamond

<< :Application of PCBN Tools in Machining Brake Disc

<< :What are the causes of blade wear in cutting? How to deal with it?

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088