Case Studies

Case I

|

Workpiece |

Gear |

|

Cutting inserts |

PCBN – SNGN201020 |

|

Workpiece Materials |

40CrMo (45-55HRC) |

|

Cutting Parameters |

Roughing: Ap=4mm, f=0.7mm/r |

|

Finishing: Ap=0.5mm, f=0.6mm/r |

|

|

Cutting Method |

Gear Top cylindrical Turning |

|

|

|

Comparison

|

Comparison |

Cutting Speed |

Efficiency |

Life |

|

Carbide inserts |

20m/min |

20h/pcs |

0.25pcs/edge |

|

MORESUPERHARD

CBN inserts |

50m/min |

2h/pcs |

2pcs/edge |

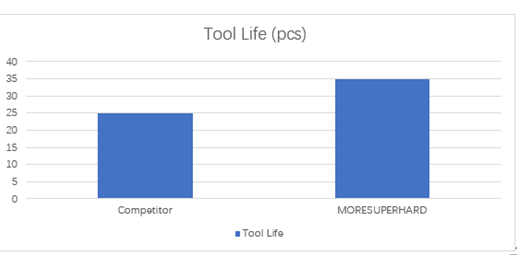

Case II

|

Workpiece |

Bearing |

|

Cutting inserts |

PCBN—SNGN150720 |

|

Workpiece Materials |

Gr15 (55-62HRC) |

|

Cutting Parameters |

Vc=120m/min |

|

Ap=4mm |

|

|

f=0.1mm/r |

|

|

Cutting Method |

Cylindrical / Face turning |

|

|

|

Case III

|

Workpiece |

Rotary Support Bearing |

|

Cutting inserts |

PCBN—RCGN090700 |

|

Workpiece Materials |

42CrMo (47-55HRC) |

|

Cutting Parameters |

Vc=90m/min |

|

Ap=0.2mm |

|

|

f=0.3mm/r |

|

|

Cutting Method |

Inner Circle Turning |

|

|

Comparison

|

Comparison |

Cutting Speed |

Efficiency |

Life |

|

Coated Alloy |

50m/min |

2h/pcs |

1pcs/edge |

|

MORESUPERHARD

CBN inserts |

90m/min |

30min/pcs |

4pcs/edge |

Case IV

|

Workpiece |

Crankshaft |

|

Cutting inserts |

PCBN—DNGA110408 |

|

Workpiece Materials |

42CrMo (42-47HRC) |

|

Cutting Parameters |

Vc=170m/min |

|

Ap=0.3mm |

|

|

f=0.1mm/r |

|

|

Cutting Method |

Excircle Interrupted Wet Turning |

|

|

Comparison

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088