News

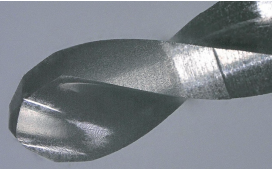

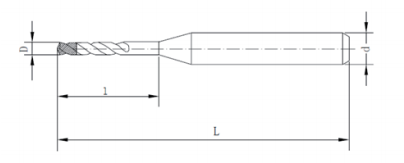

Home / News > PCD Micro Drills

Application

Suitable for monocrystalline silicon and quartz Ceramics, etc. are fragile and difficult to process Material drilling

Advantage

-φ0.1mm~φ2.0mm Any size according to customer needs

-Can be customized Fast product within 5~10 days Delivery capability

-This product has been large and stable Supply to Japanese and Korean companies

<< :Polycrystalline diamond product series

<< :High-efficiency machining plan for aerospace titanium alloy structural parts

More Superhard supplies domestic 8-inch CVD diamond heat sink wafers, mass-produced in February 2026, with ultra-high thermal conductivity and excellent thermal expansion matching. Widely used in semiconductor, laser, aerospace and other fields, please call the consultation hotline for details.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088