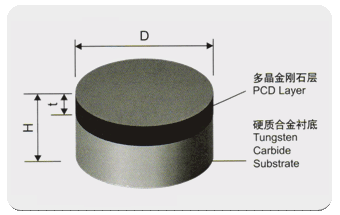

1. PDC

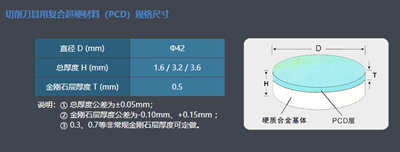

PDC Diamond composite is made by sintering diamond and cemented carbide substrate under high pressure and high temperature, which has the characteristics of high hardness and good wear resistance, it is an ideal material for manufacturing cutting tools, drilling bits and other wear-resistant tools.

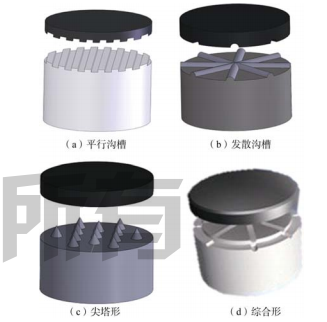

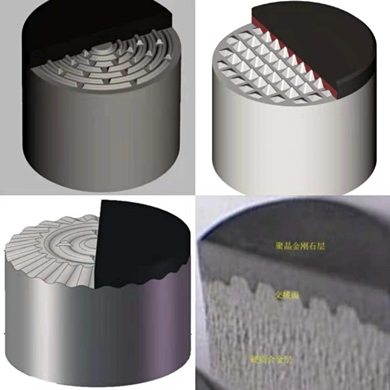

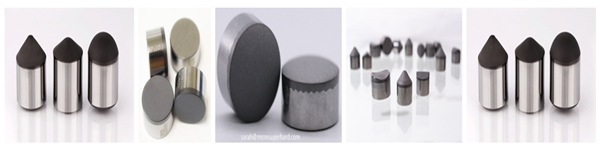

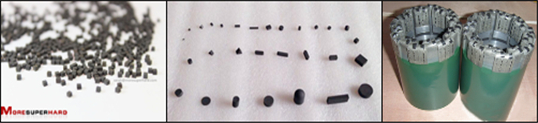

2. PDC for drilling

Suitable for soft to medium hard geological drilling, with high impact toughness and thermal stability, heat resistant temperature up to 750℃ (two minutes), this product is available with flat and a variety of groove surface combination type, and can be designed according to user needs groove, grinding, polishing, chamfering, etc., can provide special shape products.

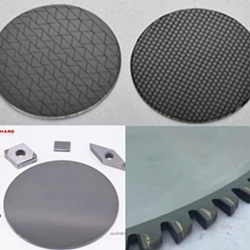

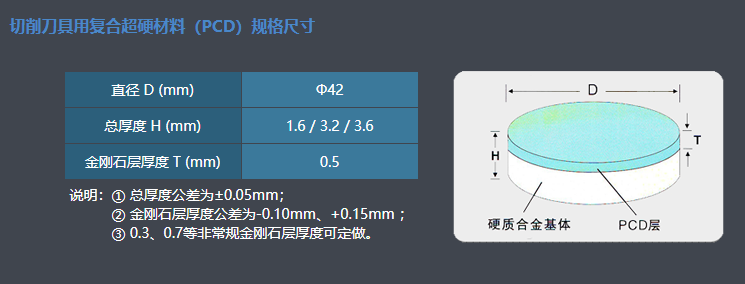

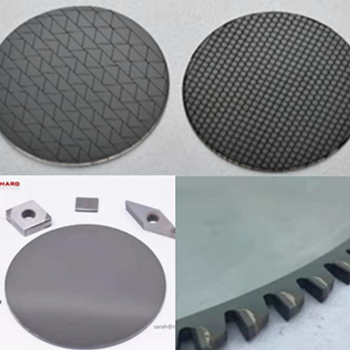

3. PDC for mechanical cutting tools

Suitable for cutting high hardness alloy, wood, ceramic and other non-metallic, nonferrous metal and other metal cutting and processing, has the high hardness and wear resistance, high cutting precision, at the same time according to user needs, will be growing product processing square, triangle, fan and other shapes, can be used for making wear-resisting devices, drill bit, top and bit teeth (such as spherical shape, cone).

According to the different performance can be divided into wear - resistant, impact - resistant or integrated products

Common models: 0806130 4130 8131 3160 8161 0161 3161 6190 8191, 1916250, etc.

Different types of diamond composites:Flat, bread, tapered, roof, etc.

The production process of the bit:

https://www.163.com/dy/article/FANDD3P20514BRHJ.html

https://www.youtube.com/watch?v=5UPk9YFoeHw

https://www.youtube.com/watch?v=elBEsb6iuCg

https://www.youtube.com/watch?v=rQi9LLQl1Bg

4. Weld the PDC to the bit:

https://www.youtube.com/watch?v=N3fJ20XXPXc

PDC Blank

PCD cutting tools are mainly used in the processing of non-ferrous metals and their alloys, engineering ceramics, stone, wood, carbon fiber plastics, synthetic wire and other non-metallic materials. At present, it has been widely used in automobile engine and its accessories, high-precision medical instruments, precision electronic components, aerospace equipment and other fields.

Grit: 1μm, 5μm, 10μm, 25μm.

5. TSP Diamond

Synthetic diamond polycrystalline is a kind of diamond polymer formed by sintering diamond and binder at high temperature and ultra-high pressure. Synthetic diamond polycrystalline has the characteristics of high wear resistance, high thermal stability and compact and uniform structure, and is widely used in the manufacture of petroleum, geological drill, diamond processing and mechanical processing tools. It is generally used as a guard diameter.

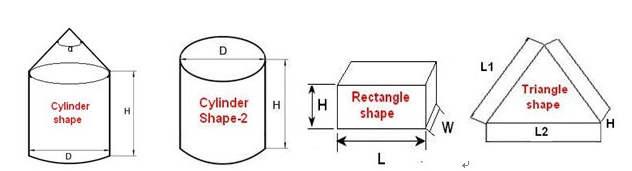

Shape: cube, cylinder, disc, rectangle, triangle, hemispherical, ellipse, etc.

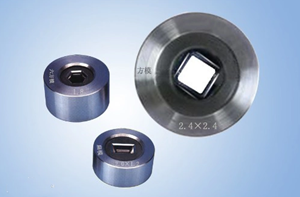

6. wire drawing mold

Usually refers to a variety of metal wire drawing die, as well as pull fiber drawing die. All drawing dies have a hole in the center of a certain shape, round, square, octagonal or other special shape. Metal decreases in size and even changes shape as it is pulled through the die hole. A steel die is sufficient for drawing soft metals such as gold and silver. The die can have multiple holes of different sizes.

Use: wire-drawing die wide range of USES, such as electronics, radar, and TV, instruments and high precision wire and used in the aerospace and other commonly used tungsten, molybdenum wire, stainless steel wire, wire and cable wire and all kinds of alloy SiDou with diamond die is drawn out, diamond die as a result of natural diamond as the raw material, which has strong wear resistance, high service life.

Type of drawing mold

1, steel mold - pull soft metal (such as gold and silver) when the steel die is enough, the steel die can have a number of different aperture holes.

Tungsten Carbide Nib is generally used in the drawing of steel wire. The typical structure of this mold is a cylindrical (or slightly tonal) carbide die core closely embedded in a circular steel case. There are Bell radius (Bell radius), Entrance angel (Entrance angel), deformation (approach Angle), sizing belt (bearing) and exit Angle (back relief) in the inner hole of die core.

3, steel wire mold - pull non-ferrous metal wire, such as copper, aluminum, and more similar wire mold drawing die, some differences in the shape of the inner hole.

4, polycrystal mold - fine drawing line can be used to polycrystal mold (artificial diamond), and the use of natural diamond drawing mold.

Video:

https://www.youtube.com/watch?v=86OrJSYzTNY

https://www.youtube.com/watch?v=QTdLyObDF_8

https://www.youtube.com/watch?v=IgpOVMZ1oko

https://www.youtube.com/watch?v=kaHHu7vk8-A

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088