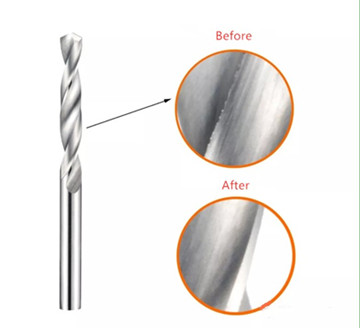

1. Highlight chamfering tool

|

Tool specifications |

Φ1~Φ4 |

|

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 40

All reverse passivation, set the time according to the passivation value.

Ensure that the cutting edge passivation value is 3~4um.

|

|

Tool specifications |

Φ6~Φ25 |

|

Specification of passivation sand before coating |

400 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

400 |

|

Passivation time after coating |

Frequency: 40

All reverse passivation, set the time according to the passivation value.

Ensure that the cutting edge passivation value is 3~4um.

|

2.

|

Tool specifications |

Φ1~Φ4 |

|

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds

|

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 40

1 to 1 ratio of positive and negative passivation.

Ensure the blade passivation value of 6~7um.

|

|

Tool specifications |

Φ6~Φ25 |

|

Specification of passivation sand before coating |

400 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds |

|

Specification of passivation sand after coating |

400 |

|

Passivation time after coating |

Frequency: 40

1 to 1 ratio of positive and negative passivation.

Ensure the blade passivation value of 6~7um. |

3. Milling cutters (forming cutters, arc cutters)

|

Tool specifications |

Φ1~Φ25 |

|

Specification of passivation sand before coating |

600 |

|

Passivation time before coating: Frequency |

30

Forward rotation: 30

seconds Reverse rotation: 30 seconds |

|

Specification of passivation sand after coating |

600 |

|

Passivation time after coating |

Frequency: 30

seconds Reverse rotation: 30 seconds |

Precautions

1. Replacement of passivated sand. When the passivation time of 400# sand tool is more than 20 minutes, the sand needs to be replaced or redeployed.

2. After the replacement of new sand, the passivation time of the first mode tool should be reduced. The passivation time cannot be reached once, but should be gradually extended to the range.

3, for the small number of sample knives, clamping should be separated from the isolation of clamping passivation.

4. The passivation time of the first mode tool at work should be reduced by 3 minutes every day. The passivation time should not be put into place once, and the passivation time should be gradually extended to the range.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088