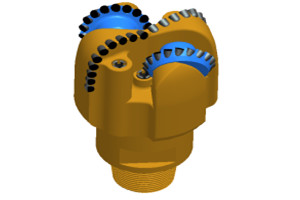

What is PDC drill bits?

A PDC (Polycrystalline Diamond Compact) drill bit is a specialized tool used in drilling operations. It is commonly used in the oil and gas industry for drilling through various formations, including hard rocks, shale, and limestone. The PDC drill bit features a diamond-enhanced cutting surface made from synthetic diamonds, which are extremely hard and wear-resistant. This cutting surface allows the bit to penetrate the rock more efficiently and with less vibration, resulting in faster drilling speeds and increased productivity. PDC drill bits are known for their durability, longevity, and ability to handle highly abrasive formations.

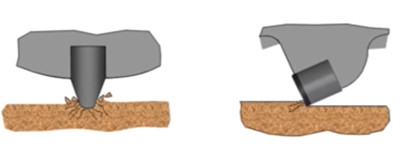

The working principle of PDC drill bit

The PDC bit breaks the rock by cutting. The self-sharpening cutting teeth can easily cut into the formation under the action of drilling weight, and move forward to shear rock under the action of torque. Multiple PDC cutting teeth work at the same time, there are many free surfaces of the rock at the bottom of the well, and the rock is easily broken under the action of shearing, so the rock breaking efficiency is high and the drilling speed is fast.

Correct use of PDC drill bit

1.PDC bits work best in large homogeneous soft to medium hard formations.

2.It is not suitable for drilling gravel layers and soft-hard formations.

3.Drilling with low drilling pressure, high speed, and large displacement, the drill bit works well.

4.Before the drill bit goes into the well, the bottom of the well should be cleaned to ensure that there is no metal falling. When the drill bit is just going down the well, it should run with a small drilling pressure and a low speed, and resume normal drilling after the bottom of the well is formed.

What is the difference between PDC cutter used in oil drilling and coal mining?

Composition: PDC composite sheets used in oil drilling and coal mining are typically made of similar materials. They consist of a layer of polycrystalline diamond compact (PDC) bonded to a tungsten carbide substrate. This composition provides hardness, wear-resistance, and toughness necessary for drilling in hard formations.

Design: PDC composite sheets for oil drilling are often designed with a more aggressive cutting structure to handle the challenging rock formations encountered in oil drilling. On the other hand, PDC sheets for coal mining may have a different design, focusing on optimized cutting efficiency and coal cutting capabilities.

Cutting Structure: The cutting structure of PDC composite sheets used in oil drilling is usually designed with larger, more durable PDC cutters to withstand the high forces and abrasive drilling conditions encountered in deep oil wells. In contrast, PDC sheets for coal mining may have a different cutter configuration, optimized for the specific requirements of cutting through coal seams.

Application: PDC composite sheets used in oil drilling are primarily employed in drilling wells for oil and gas exploration and production. They are used to drill through various formations encountered in the process. PDC sheets for coal mining, on the other hand, are specifically used for excavating and cutting coal seams in underground coal mines. While there are similarities in terms of materials used, the specific design and application considerations make the PDC composite sheets for oil drilling and coal mining different from each other.

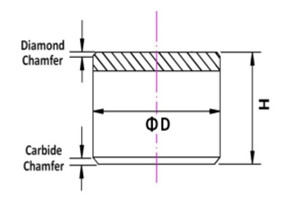

Moresuperhard provide PDC cutter for PDC drilling bits

| Products | Model | Diameter | Total Height | Height of Diamond | Diamond chamfer | Carbide chamfer |

|

PDC (polycrystalline diamond compact )cutter |

1313 | 13.44±0.03 | 13.2±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° |

| 1308 | 13.44±0.03 | 8.0±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 1304 | 13.44±0.03 | 4.5±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 1010 | 10.00±0.03 | 10.0±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 1008 | 10.00±0.03 | 8.0±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 1004 | 10.00±0.03 | 4.5±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 0810 | 8.00±0.03 | 10.0±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 0808 | 8.00±0.03 | 8.0±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° | |

| 0804 | 8.00±0.03 | 4.5±0.10 | 2.0-2.5 | 0.3x45° | 0.5x45° |

Vitrified diamond grinding wheel for grinding PDC cutter

Cylindrical grinding wheel can be used for grinding PCD bit teeth and many other parts. Vitrified diamond Cylindrical grinding wheel for rough grinding the cylinder of polycrystalline diamond compacts (PDC cutter). Compared with resin diamond grinding wheel, Moresuperhard grinding wheels lead to 35% grinding cost reduced, 40% grinding time of each PDC saved, and the size precision of PDC improved.

Customized grain sizes and specifications please contact us freely.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088