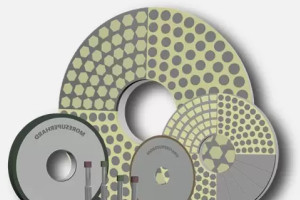

From May 31 to June 2, 2023, the 15th China International Powder Metallurgy, Cemented Carbide and Advanced Ceramics Exhibition was grandly opened at the Shanghai World Expo. Henan Moresuperhard brought double sided ceramic diamond grinding discs, vitrified diamond grinding wheels, resin diamond grinding wheels, cutting discs, internal grinding wheel and other high-precision diamond tools to the exhibition.

The exhibition hall of this exhibition is 40,000 square meters, gathering 761 Chinese and foreign enterprises, exhibiting the latest technologies in the fields of powder metallurgy, advanced ceramics, magnetic materials, and additive manufacturing. Nearly a thousand exhibits have achieved precise docking and achievement transformation to the greatest extent. The exhibition areas mainly include:

Advanced ceramics, powder metallurgy, cemented carbide, injection molding, additive manufacturing, magnetic materials and other related industries

The exhibition site is extremely hot, and our booth (h2-e717) has a constant flow of people. It has attracted high attention and recognition from production and processing enterprises such as ceramic components, magnetic materials, and hard alloys. Through exchanges and discussions with many interested customers, it provides them with professional solutions.

Due to the high hardness and high brittleness of ceramic materials, most of the processed ceramic components will produce various types of surface or subsurface damage, which will lead to a decrease in the strength of ceramic components, which in turn limits the adoption of high material removal rates. The fundamental goal for efficient grinding of ceramics is to achieve maximum material removal rates while maintaining material surface integrity and dimensional accuracy. Moresuperhard diamond grinding wheel can make the ceramic surface have good surface quality while maintaining high-efficiency grinding.

The double-end grinding disc produced by Moao, the upper and lower grinding discs simultaneously perform high-precision grinding on the two planes of the workpiece. Suitable for bearing rollers, bearing inner and outer rings, electronic parts, carbide blades, ceramic parts, aluminum alloys, copper, auto parts, air conditioning valves, blades and other products that require high precision on both ends.

Moresuperhard provides customized precision ceramic grinding, lapping and polishing services and solutions. It is difficult for ceramics to cut precise and complex contours with ordinary processing methods. The diamond wheel grinding process is an effective process for machining ceramic materials. The precision tolerance of the precision profiler of this grinding process is less than 0.005mm. Machining processes include efficient diamond wheel profiling and ceramic profile grinding.

In general, this exhibition has gained a lot. In addition to communicating with our new and old customers at the booth, we also saw a lot of advanced ceramic products and crafts at other booths. Moresuperhard will continue to create high-precision products, focusing on grinding and polishing technology solutions. Looking forward to our next meeting.

<< :The Characteristics and Processing Range of Cermet Cutting Tools

<< :Key points and difficulties in the preparation of silicon carbide substrates

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088