The 6th A&G EXPO came to a perfect conclusion on September 22. As a superhard abrasive tool manufacturer, Moresuperhard company also participated in this industry event.

This time Moresuperhard mainly exhibited ceramic bonded diamond products. It mainly includes ceramic bond optical profile grinding wheels, ceramic diamond peripheral grinding wheels, 10000# ceramic diamond grinding wheels specially used for single crystal diamond cutting tools grinding, back grinding wheels, and ceramic diamond cylindrical grinding wheels.

The applications of vitrified diamond grinding wheel

Ceramic bonded diamond grinding wheels are mainly used in the machining of hard alloys, semiconductor silicon wafers, diamond composite sheets, diamond tools, new engineering structural ceramics, gems, crystals, magnetic materials and other high-hard and brittle materials, and have achieved good results.Our customer also use vitrified diamond grinding wheel for grinding this materials with different workpieces.

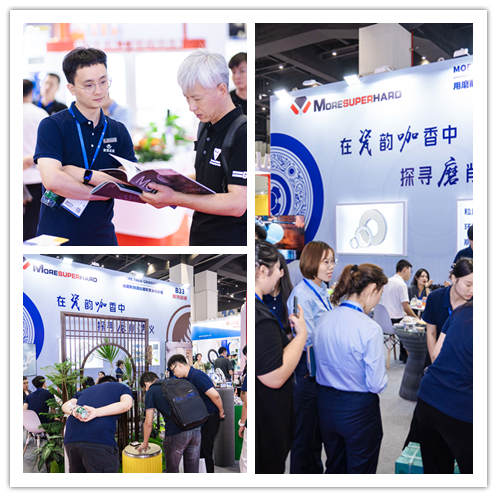

Specifical design of moresuperhard's booth

Moresuperhard designed the fusion of Chinese ceramics and coffee for this exhibition. Moresuperhard 's booth attracted many customers at home and abroad to come and communicate.

Moresuperhard professional sales help our customer solve their grinding problems

Moresuperhard provide customized diamond grinding wheel for different materials and workpieces.Moresuperhard is focus on providing grinding solutions for superhard materials like polycrystalline diamond,mono crystal diamond ,cbn,cermet and other precision cutting tools.Moresuperhard provide diamond grinding wheel for different grinding machine like cutting tools grinding machine,cylindrical grinding machine,peripheral grinding machine and optical profile grinding machine.

Moresuperhard also learn a lot of knowledge from abrasives and grinding exhibition.Moresuperhard will continue to research and develop and make progress in producing high-quality diamond grinding wheels. Looking forward to see you next time.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088