Grinding difficults in processing stainless steel

In order to meet the surface quality and processing accuracy requirements, stainless steel parts usually use grinding processing methods. Due to the high toughness, small thermal conductivity and small elastic modulus of stainless steel, the following problems often occur during grinding:

(1) The grinding force is large, the grinding temperature is high, and the machined surface is easily burned;

(2) Work hardening trend is serious;

(3) Wear debris easily adheres to the grinding wheel and blocks the pores of the grinding wheel;

(4) Grinding scratches appear on the surface of the workpiece; (5) The workpiece is easily deformed.

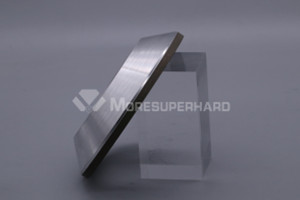

Recommand Resin bond CBN grinding for grinding stainless steel

By using Moresuperhard resin CBN grinding wheels to grind a large number of stainless steel workpieces, we concluded that reducing the adhesion and clogging of the grinding wheel is an important factor in improving grinding efficiency. The grinding wheel must be trimmed frequently during processing to maintain the sharpness of the cutting. Therefore, when choosing a grinding wheel, the resin CBN grinding wheel with good self-sharpening properties is the first choice. As for the hardness of the CBN grinding wheel, it is also one of the important factors.

Principles for Selection of Grinding Parameters for Stainless Steel Workpieces

(1) Selection of grinding wheel speed vs: From the perspective of improving the cutting performance of the grinding wheel, a higher grinding wheel speed vs should be used when grinding stainless steel. However, because a high grinding wheel speed will clog the grinding wheel, it will lose cutting ability, and Grinding burns are prone to occur and the machined surface is easily scratched, so the grinding wheel speed should be selected carefully when grinding stainless steel. Practice has proven that the grinding wheel speed for grinding stainless steel should not exceed 25m/s.

(2) Selection of workpiece speed vw: The workpiece speed vw should change with the grinding wheel speed vs. The basic principle is that when vs is low, vw is also low; when vs is high, vw will also increase. This can keep the chip cross-sectional area basically constant. Change. vs and vw change proportionally, which can reduce grinding scratches. Generally, the workpiece speed and grinding wheel speed can be selected in the range of 1/60 to 1/100.

(3) Selection of grinding depth ap: When grinding materials with high toughness and high plasticity such as stainless steel, when the grinding depth is less than or equal to 0.01mm, the grinding wheel is prone to adhesion and blockage, and burns and scratches are prone to occur. The reason is that the sand grains have a certain fillet radius. When the grinding depth is too small, the sand grains cannot cut into the matrix, but scratch and squeeze on the surface, causing the grinding force and grinding heat to increase, and the chips are easy to adhere and block the grinding wheel. , reducing the cutting ability of the grinding wheel and causing scratches on the workpiece surface. When rough grinding, it usually takes 0.02~0.05mm, and when fine grinding, it usually takes about 0.01mm.

(4) Selection of feed amount: The feed amount is generally calculated based on the grinding wheel width B. For cylindrical grinding of stainless steel, the feed amount for rough grinding can be (1/4~1/6) B, and the feed amount for fine grinding can be (1/8~1/10) B. When the grinding depth is large, the smaller value is used, and when the grinding depth is small, the larger value is used. When the workpiece has good rigidity, the feed amount can be increased appropriately. When grinding slender workpieces and thin-walled workpieces, in order to prevent deformation, a large feed rate and a small grinding depth can be used for grinding. When internal cylindrical grinding, the feed amount for rough grinding can be taken as (1/3~1/4)B, and the feed amount for fine grinding can be taken as (1/6~1/8)B. When grinding shallow holes, take the larger value, and when grinding deep holes, take the smaller value. When the requirements for machining accuracy and surface roughness of the workpiece are high, the feed rate should be appropriately reduced.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088