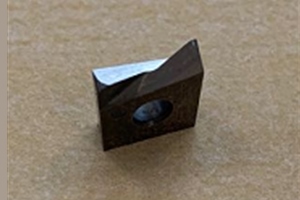

Cutting tools: TORO

Material: carbide

Machine: AGATHON Evo Penta

Software options: FRP free reference plane, Edge grinding wheel corner grinding

Special device: horizontal turning table

Cooling method: grinding oil cooling

Online cleaning: none

Machining allowance: 0.2mm

Processing time per side: 100 s (including loading and unloading and measuring time)

Drive head: lengthened/center hole positioning

Clamping head: standard

Feeding Prism: Standard

Automation

Loading and unloading: manipulator

Material tray: vertical tray or horizontal tray (horizontal tray requires electromagnetic suction head and turntable head)

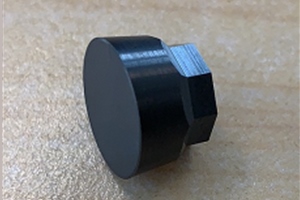

Material: ceramic

Machine: AGATHON Dom Plus

Software options: none

Special device: none

Grinding wheel: grit size 28, Φ350, wheel layer width 10mm, wheel layer thickness 10mm

Cooling method: grinding oil cooling

Dressing wheel: grit 240#

Online cleaning: none

Machining allowance: 0.7mm circumference

Processing time: 155 s (Including loading and unloading and measuring time)

Frock clamp

Drive head: standard Φ10mm

Clamping head: standard Φ8mm

Feeding Prism: Standard 800

Automation

Loading and unloading: manipulator

Material tray: vertical tray

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088