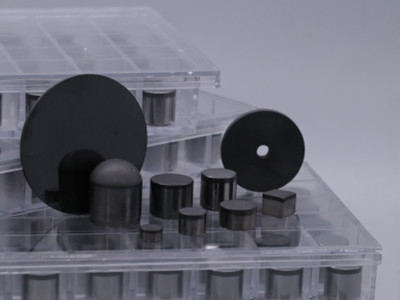

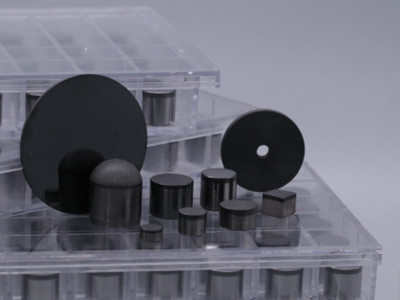

In the stone processing industry, cutting efficiency, tool life, and operational stability directly affect production cost and finished surface quality. As the functional core of stone cutting saw blades, diamond composite cutters (PDC) must operate reliably under extremely harsh conditions. This makes their design fundamentally different from PDCs used in general cutting or precision machining applications.

Stone cutting is a complex process characterized by high impact loads, severe abrasion, and elevated temperatures. Key challenges include:

As a result, stone-cutting PDCs must achieve an optimized balance among wear resistance, impact toughness, thermal stability, and structural integrity.

Compared with PDCs used in standard cutting tools, stone cutting PDCs feature a diamond layer several times to more than ten times thicker.

Stone materials often contain hard minerals such as quartz and feldspar, which cause severe abrasive wear and impact damage.

Stone cutting PDCs typically use:

Stone is inherently non-uniform and may contain hard spots, cracks, or mineral inclusions. High-quality stone cutting PDCs are engineered to:

This balanced design effectively reduces edge chipping, delamination, and premature failure.

Typical materials: Granite, Quartzite

Typical materials: Marble, Limestone

Typical materials: Slate, certain sandstones

Diamond composite cutters for stone cutting saw blades are application-specific components. Optimal performance can only be achieved when PDC design is carefully matched to stone material characteristics, cutting methods, and actual operating conditions.

Proper selection of diamond grain size, diamond strength, and diamond layer thickness can significantly improve cutting efficiency, extend tool life, and reduce overall cost per cut.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088