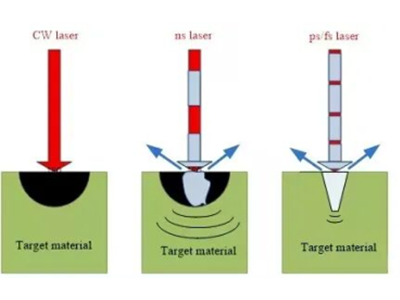

1. Pulse Duration Comparison

| Laser Type | Pulse Duration | Characteristics |

|---|---|---|

| Nanosecond (ns) | 10⁻⁹ s | Longer pulse, significant heat diffusion, larger HAZ |

| Picosecond (ps) | 10⁻¹² s | Reduced heat diffusion, cleaner edges, higher precision |

| Femtosecond (fs) | 10⁻¹⁵ s | Ultra-short pulse, almost no thermal effect (“cold machining”) |

2. Thermal Effects & Machining Quality

- Nanosecond laser: Noticeable heat-affected zone (HAZ), possible burrs, melting or cracks; suitable for marking, rough shaping, turning-like operations.

- Picosecond laser: Smaller HAZ, smoother surfaces; ideal for micro-manufacturing and precision milling-like machining.

- Femtosecond laser: Minimal heat diffusion, extremely clean ablation; best for ultra-fine finishing or transparent materials.

3. Material Adaptability

Nanosecond: Works on metal and plastic; limited for heat-sensitive materials.

Picosecond: Suitable for metals, ceramics, polymers; reduced thermal damage.

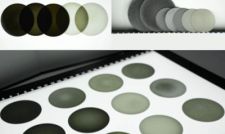

Femtosecond: Suitable for nearly all materials including glass, crystals, diamond, and brittle ceramics.

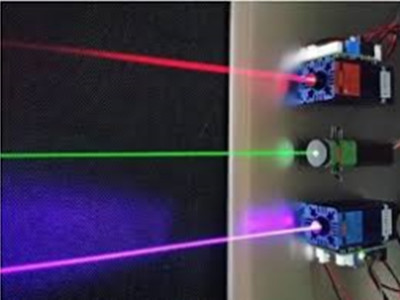

4. Industrial Laser Types Overview

- Infrared ns: Economical, reliable, widely used; limited for ultra-hard materials.

- Green ns: Higher efficiency; higher cost and integration difficulty.

- Infrared ps/fs: Emerging mainstream for carbide, PCD, ceramics; improving reliability.

- Green ps/fs: Used for high-end niche applications requiring specific absorption characteristics.

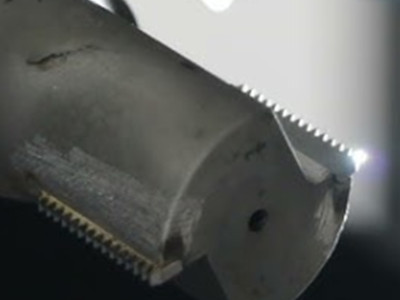

5. Moresuperhard 5-Axis Laser PCD Grinding Machine

Moresuperhard integrates ultrashort-pulse laser technology (ps or fs) with a high-precision 5-axis platform, enabling complete PCD and ultra-hard tool machining:

- Cold machining with minimal micro-cracks and perfect cutting-edge integrity.

- Five-axis synchronization allows processing of chipbreakers, flanks, helical surfaces, complex 3D geometries, and internal cooling channels.

- One machine covers rough shaping (ns), precision milling (ps), and ultra-fine finishing (fs).

- No electrode consumption compared to EDM; low operating costs and high consistency.

- Ideal for PCD/PCBN, CVD diamond, carbide, alumina, SiC, sapphire, and other brittle materials.

6. Conclusion

The progression from nanosecond to picosecond and femtosecond laser machining represents a major leap in manufacturing precision. For industries such as tooling, semiconductors, optics, medical devices, and advanced ceramics, ultrashort-pulse lasers provide unmatched accuracy and reliability. Moresuperhard’s 5-axis laser PCD grinding machine unifies roughing and ultra-precision finishing, delivering high efficiency, clean surfaces, and sub-micron accuracy.