5. Insufficient inspection of grinding machine or inappropriate machine tool

Problem 1: Loose bearings, bent main shafts, and precision of grinders are significantly reduced

Solution: Check and repair the grinder, and seek to improve its accuracy

Problem 2: The shaft diameter of the grinding wheel shaft is too small

Solution: If there is a grinding wheel with a size equivalent to the shaft, use a grinding wheel with this size

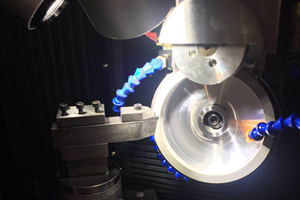

Question 3: Rough rough grinding or incorrect use of grinding wheels

Solution: Rely on the guidance of the skilled person or the manual of the grinding wheel to carry out the correct grinding operation

6. Side grinding with unsuitable grinding wheels

When using grinding wheels other than side grinding wheels, you must use grinding wheels (bowl wheels, etc.) for side grinding

7. Changes in grinding wheel quality

Question: When the grinding wheel encounters a flood or fire, the resin bond, rubber bond wheel, etc. have to change in quality

Solution: Confirm the entry way of the grinding wheel, correctly store it, consider the manufacturing date of the grinding wheel, and strictly carry out various inspections before use

8. Irregular damage

Problem: The quality of the grinding wheel is not good; the grinding wheel is pressed by heavy objects; the unreasonable installation of the grinding wheel

Solution: To ensure the quality of the product, enter the inspection to study its condition in detail and prohibit heavy objects from being pressed on the grinding wheel to install it smoothly.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088