Foreword

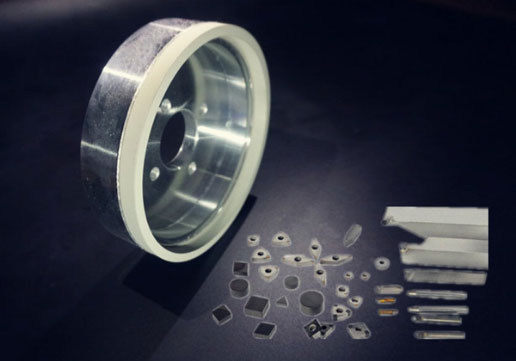

“YOUR”wheel: According to the grinding workpiece and grinding machine model, as well as the actual working conditions and customized exclusive grinding wheel.

Best grinding wheel is the best price?

I used to think,

The first consideration of industrial consumables is price.

The next step is whether it works or not.

So keep the price as low as possible.

Until I looked at the efficiency Numbers, which are pathetic,

I began to eliminate the cheap but useless grinding wheel,

Especially the kind of grinding wheel that often needs to be dressing.

The replaced grinding wheels is getting more and more.

Only to find that seemingly low unit price saves the cost of consumables,

But in the end, it didn't.

It's just a waste.

I didn't know until I asked MORE SUPERHARD

The grinding wheel is made up of abrasive, blowhole and binder.

Which can be adjusted are abrasive, grit size, binding degree, tissue, binder,

Each element has an effect on the grinding result.

MORE according to their expertise to help me prepare a grinding wheel suitable for my manufacturing process and workpiece.

Practical use really solved my current problem!

Although the custom grinding wheel price is higher than common one,

But when you see an increase in both yield and efficiency,

You will know that the money you spend will bring you a bigger profit,

Instead of make the grinding wheel gathering dust in the corner.

Best grinding wheel is the best material?

When I ordered grinding wheels in the past , I always thought that the more expensive the grinding wheel, the better it would be. Therefore, I always asked the supplier to make my grinding wheels with the best diamond raw materials.

However, in fact, I was so focused on quality that I ignored other influence factors. As a result, I have to spend a lot of money on purchasing grinding wheels every year, but it does not improve my grinding efficiency.

On the contrary, there are always a variety of problems, poor grinding force, even damage to the workpiece. It was very upsetting to me.

Until I had an in-depth discussion with MORE, they asked me about the model of the grinder, the processing parameters, the current problems and my requirements.

They recommended me to use sharp diamond raw materials to increase sharpness. Although the strength of diamond was reduced and the life of diamond was shorter than before, the processing efficiency was greatly improved, and we completed more grinding tasks in a shorter time.

More importantly, the grinding wheel is cheaper and meets my grinding requirements.

I am happy to find the MY wheel.

Best grinidIng wheel is "YOUR" whee'l!

The best grinding wheel is not the lowest price, nor the best diamond raw material, but suitable for you, exclusive to your grinding wheel.

“Henan More Super Hard Product Co.,Ltd” devoted to offer diamond &CBN tools following customer special specification or FEPA standard. Over 1000 customers benefit from our skill of development, manufacture and application, they find a way to make the grinding and cutting high efficiency, high precision, and better economy. MORE is looking forward to working with you to create your own "YOUR" wheel.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088