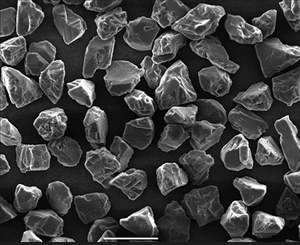

The grinding process of a single abrasive grain is roughly divided into three stages: Slip, scribing and cutting.

(2)Scribing stage: As the depth of squeezing of the abrasive particles increases, the pressure between the abrasive particles and the surface of the workpiece gradually increases, and the surface layer transitions from elastic deformation to plastic deformation. At this time, the squeeze friction is intense, and a lot of heat is generated. When the metal is heated to the critical point, the normal thermal stress exceeds the critical yield strength of the material, and the cutting edge begins to cut into the surface layer of the material. The slip causes the surface layer of the material to be pushed to the front and both sides of the abrasive grain, so that the abrasive grain scores groove marks on the surface of the workpiece, and the two sides of the groove mark are raised. The characteristics of this stage are: plastic flow and bulge on the surface of the material, because the cutting thickness of the abrasive grains does not reach the critical value of chip formation, and cannot form chips.

(3)Cutting stage: when the squeezing depth increases to the critical value, the cut layer slips along the shear plane obviously under the squeezing of the abrasive grains, and the formed chips flow out along the rake face. This is called the cutting stage.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088