The processing of PCD inserts mainly include polishing pcd blanks, cutting pcd blank (EDM), welding pcd inserts and grinding pcd inserts, etc. One of the key technologies of PCD tool manufacturing is the quality of cutting edge grinding. In order to obtain good PCD cutting edge quality, the most ideal processing method is still using vitrified diamond wheel to grind pcd. How to use our diamond wheel to grind R0.01mm PCD inserts.

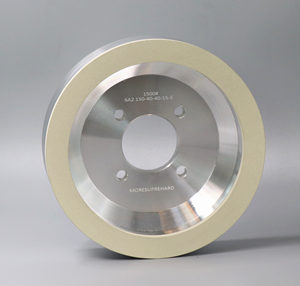

1.Selection of vitrified diamond wheel for PCD grinding :

Advantages

* porous structure vitrified diamond wheel can prevent vertical streaks on workpiece and improve surface quality. Efficient heat removal with open structures that carry coolants into the work zone resulting in less thermal damage to metals.

* lower grinding costs by allowing to produce more superior edges in less time.

* compare to resin bond and metal bond, our vitrified diamond wheels have high grinding efficiency, good self sharpening and high wear resistance and easy dressing etc.

* Vitrified bond wheels offer tool life greater than 150 times that of a resin bond wheel and can be easily trued and dressed on the machine.

* PCD tools can reach high efficiency , good surface finish and edge no chipping.

Grain size of vitrified diamond wheel

vitrified diamond grinding wheels for sharpening PCD inserts the grain sizes are used: rough grinding D20, finish grinding D15 and super finish grinding D6, D3,D1......

Our vitrified diamond wheels are used on MYTECH PCD grinding machine, Corborn and Anca......

2.Selection of PCD grinding machine

* Equipped with high precision camera system and measurement software. PCD tips can reach R 0.01mm grinding work

* adopting high rigidity bed, high accuracy and good stability. high quality casting of column and base have good rigidity working stable.

* spindle can be raised and lowered ( vertical movement), quick change tool. Grinding Spindle: With High Precision And Variable Frequency, The Direct-Drive Spindle Power Is 3Kw; Max Speed Is 4000r/Min

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088