Cutting

Home / Cutting / Tool Blanks > CVD (Chemical Vapor Deposition) Diamond Plates

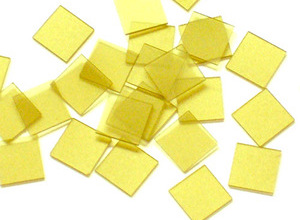

CVD Synthetic Diamond Plates Wholesale

cvd diamond plate sheets for sale

More Superhard also can make

- cvd diamond for dressing tools

- cvd diamond coating for thermal management

- cvd diamond wire drawing die blanks

- cvd diamond for cutting tools

- cvd diamond for optical windows

What is the CVD diamond

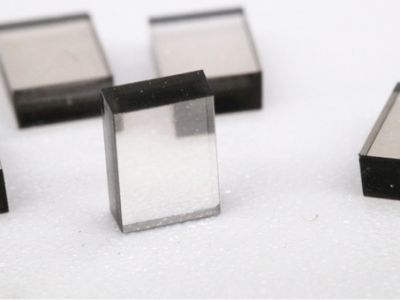

CVD synthetic diamond is an acronym for chemical vapor deposition diamond, pure diamond polycrystalline structure, no cutting surface, no metal binder. More SuperHard offers a full range of CVD diamond grinding, cutting, dressing, coating, thermal and wear part solution and service

Applications of CVD diamond

CVD diamond plate is used for semi-finishing, finishing, super finishing and continuous cutting of ultra precision cutting tools. In addition, the CVD diamond is also used for other high-tech applications (such as diamond dresser, wire drawing die, electronics, optical window, heat spreader and gem stone industry, etc).

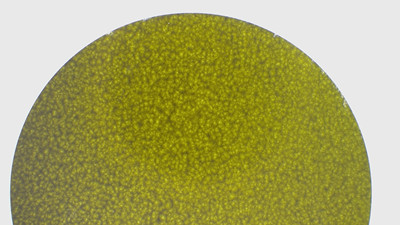

( Imaging of CVD optical Windows under the microscope )

The specification of CVD diamond plates

|

Model |

length * width * thickness (mm) |

|

CVD diamond plate |

1 * 1 * 1 |

|

2 * 2 * 1 |

|

|

3 * 3 * 1 |

|

|

4 * 4 * 1 |

|

|

5 * 5 * 1 |

|

|

6 * 6 * 1 |

|

|

7 * 7 * 1 |

|

|

8 * 8 * 1 |

|

|

9 * 9 * 1 |

|

|

10 * 10 * 1 |

|

|

11* 11 * 1 |

|

|

12 * 12 * 1 |

|

|

Thickness of CVD diamond plate from 0.3mm to 3mm

Other sizes of cvd diamond plates can be made according to customer's requirement |

|

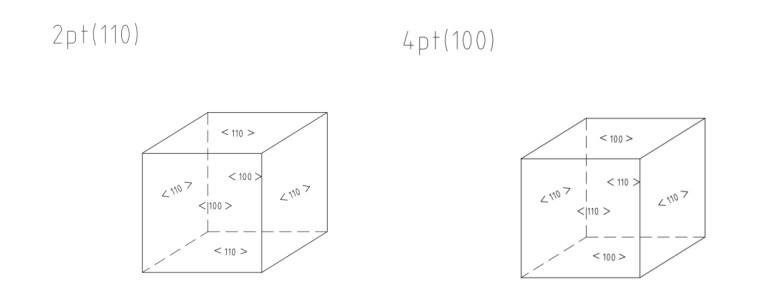

Single Crystal orientation

2pt(110): top and bottom 110+2 sides 110+2 sides 100

4pt(100): top and bottom 100+4 sides 110

How many types of cvd diamond plates

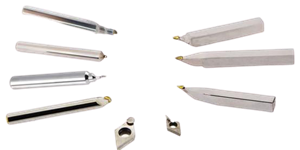

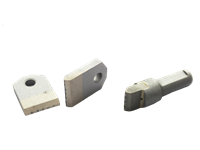

1. CVD diamond plates for cutting tools

Benefits of cvd diamond plates for cutting tools

- Because the concentration of atomic hydrogen produced by arc discharge is relatively high, the CVD tool blank processed by the DC arc plasma jet also has a higher thermal conductivity than the tool blank processed by other methods even at higher grown rate. This shows that CVD is obviously beneficial to heavy high-speed cutting operations.

- The CVD diamond tool is made with CVD diamond blanks without any binder, sharing the same surface smooth finish as the natural single crystal diamond.

- The working life of CVD diamond cutting tools are 100 times higher than that of hard alloy.

Applications of cvd plates: non ferrous materials, ceramic, abrasive composites, high silicon - content aluminum alloy, graphite and other difficult machining materials.

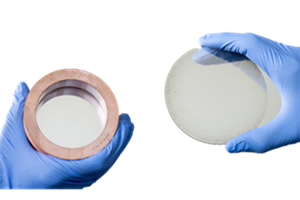

2. CVD diamond for optical windows

The high-quality CVD diamond has excellent optical performance, it has high optical transparency in х -RAY, UV, visible lightinfrared light, even up to the millimeter-wave.

Excellent transparency in the optical, high thermal conductivity, extraordinary high hardness and high fracture toughness, and very low thermal expansion coefficient make cvd diamond an ideal material for highly demanding optical window the broad band optical transparency

Applications of cvd diamond plates: for optical windows. Such as high power laser windows, high power micromave windows and durable windows, etc

The properties of optical grade CVD diamond

|

Transmission |

225nm To Far Ir 70% @10μm |

|

Refractive Index |

2.38 @ 10μm, 2.41@500 Nm |

|

Absorption Coefficien |

<=0.10 Cm^-1 @10 Μm |

|

Bandgap |

5.45ev |

|

Double Side Surface Roughness |

Ra 10nm |

|

Flatness |

4um/Cm |

|

Thickness <= 0.3mm Diameter<= 20mm |

3. CVD diamond blanks for dressing tool

Chemical vapor deposition(CVD) for dressing tools is made by laser cutting CVD diamond thin-film. CVD diamond blanks are suitable for various dresser tools,

- Single - point cvd dresser

- Multi - point cvd dresser,

- CVD rotary dresser,

- CVD diamond dressing roller

CVD diamond blanks produced by the high quality semitransparent polycrystalline diamond, with no binder phase, have excellent thermal stability and high thermal conductivity.

The cvd diamond grade includes (standard grade and high quality grade)

|

Performance |

Standard |

High Quality |

|

Vicker Hardness |

8000 Kg/Mm^2 |

10000 Kg/Mm^2 |

|

Density |

3.51g/Cm^3 |

3.51g/Cm^3 |

|

Young’s Modulus |

1000 Gpa |

1100 Gpa |

|

Thermal Conductivity |

1000w/M.K |

1500w/M.K |

|

Chemical Stability |

Insoluble In All Of Acid And Alkali |

|

|

Break Strength |

350 Mpa |

550 Mpa |

|

Wear Ratio |

200000 |

400000 |

|

Thermal Stability |

800°C |

800°C |

4. CVD diamond wire drawing die blank

Wire drawing is a metal-working process relies on a combination of a die and/or a series of dies to pull or draw a wire to a chosen gauge and is utilized to reduce the cross section of a wire.

CVD diamond consist of a metal case and a nib made from monocrystalline diamond or polycrystallie diamond (PCD) or CVD diamond.

Applications of cvd diamond : wire drawing of stainless steel, tungsten, molybdenum, copper, aluminum and others alloy, etc

Size of CVD diamond die blanks

|

Product |

Size (mm) |

Shape |

|

|

CVD Serie |

D |

T |

D----the diameter

T-----the thickness

|

|

CVDD2010 |

2.0 |

1.0 |

|

|

CVDD2512 |

2.5 |

1.2 |

|

|

CVDD3015 |

3.0 |

1.5 |

|

|

CVDD4020 |

4.0 |

2.0 |

|

|

CVDH4020 |

4.0 |

2.0 |

|

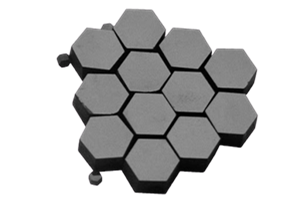

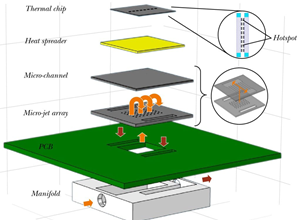

5. CVD Diamond for thermal management / CVD diamond heat sinks (CVDK)

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088