Cutting

Home / Cutting / Tool Blanks > Ultra Thick PCD Blanks for Solid PCD Tools

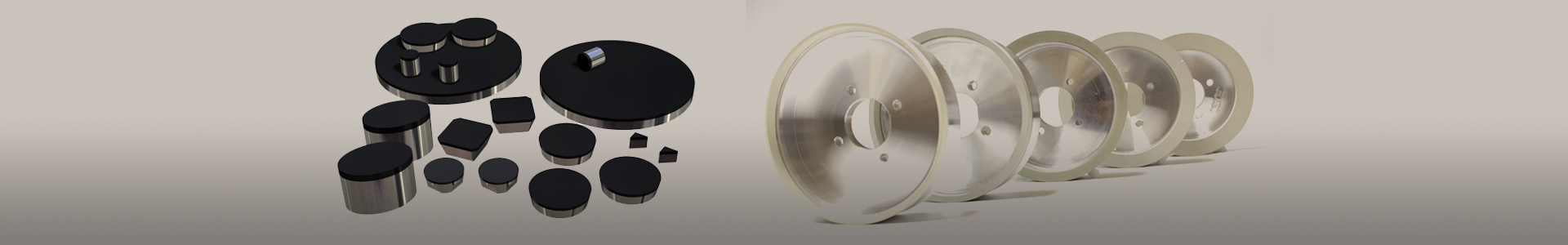

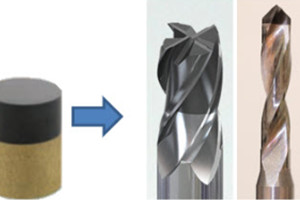

Ultra thick pcd blanks are mainly used in solid PCD tools, such as solid PCD drills, milling cutters, micro-blade tools, etc.

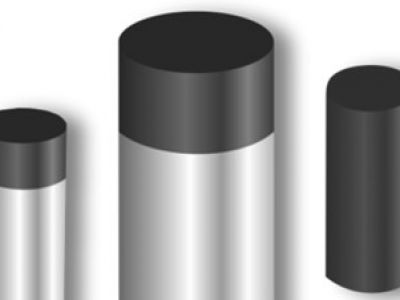

superhard layer can be as thick as:4mm-6mm

Diameter:1mm-19mm

solid PCD tools are especially favored in the cutting of glass, ceramics, graphite, sapphire, carbon fiber and other materials.

Introduction of Ultra Thick PCD blanks

Diamond (or PCD-polycrystalline diamond) tools, in the right application, last 20 times longer than equivalent carbide tools. Users want longer life and better cutting performance compared to the shearing edges of conventional PCD tools. A new generation of solid PCD helical end mills and drills will further expand this advantage. In 3C (electronics) and aerospace manufacturing, there is a huge demand for cutting tools that can provide higher productivity and quality. In addition, the top-notch production process of overall PCD has matured and become more economical.

Advantages of ultra thick pcd blanks

1.Flexibility makes PCD top tool quality outstanding PCD tool geometry offers complete flexibility and superior cutting performance compared to equivalent tools with brazed PCD inserts.

Traditional PCD rotary cutting tools typically have PCD inserts brazed to carbide tool bodies. While PCD can extend the life of the cutting edge, by design the cutting edge geometry is a sheared (straight) margin with a straight rake angle. This geometry inherently limits the performance of the tool. With solid PCD tools, designers have more flexibility to create a variety of unique geometries to meet different cutting applications in the same way as traditional carbide tools. This applies not only to cutting contours, but also to the grinding of flute and backlash geometries, which are critical for both chip formation and evacuation.

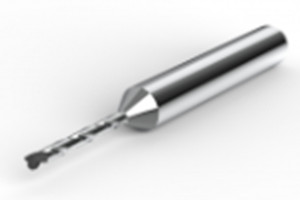

2.Ability to make miniature, smaller diameter cuttin tools

Brazed PCD knives typically have a minimum diameter of 6mm, but solid tip PCD knives can easily be made smaller than this. Micro tools (drills and end mills) are widely used in the 3C industrial.

3.Longer tool life

Unlike coated carbide tools, these new drills and end mills can be easily re-sharpened multiple times, providing high wear resistance and effectively extending tool life.

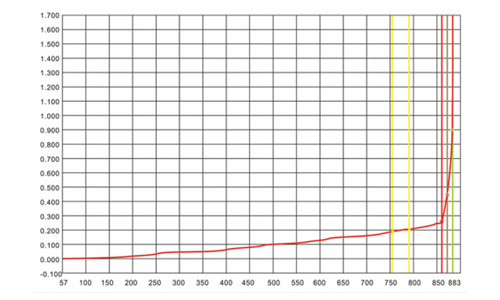

Heat resistance test

The ultra thick pcd blank has good heat resistance: the recommended vacuum welding temperature is ≤790°C, and the shedding temperature of the polycrystalline layer is as high as 870°C.

Applications of solid PCD tools

Application field New solid PCD, expanded possibilities for machining cemented carbide and other hard and brittle materials to smaller diameters, as well as other machining of aluminum, titanium and composites. Integral sintered PCD drill bits with double apex angle, suitable for different CFRP and GFRP materials, aluminum alloy materials and brittle materials, can be used for abrasive materials in aerospace and all composite material processing industries Widely used in 3C (electronics) and aerospace manufacturing. While punches and dies often require tools with a diameter of less than 6 mm, monolithic PCD is widely used with new geometries and miniaturized designs.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088